System SLP2

Advanced Automation to Maximize Log Yield and Minimize Operational Costs

SLP2 is the next stage in increasing profits from small- to medium-sized logs.

Доступно за замовленням, від:

Доступно за замовленням, від:

146,506 €

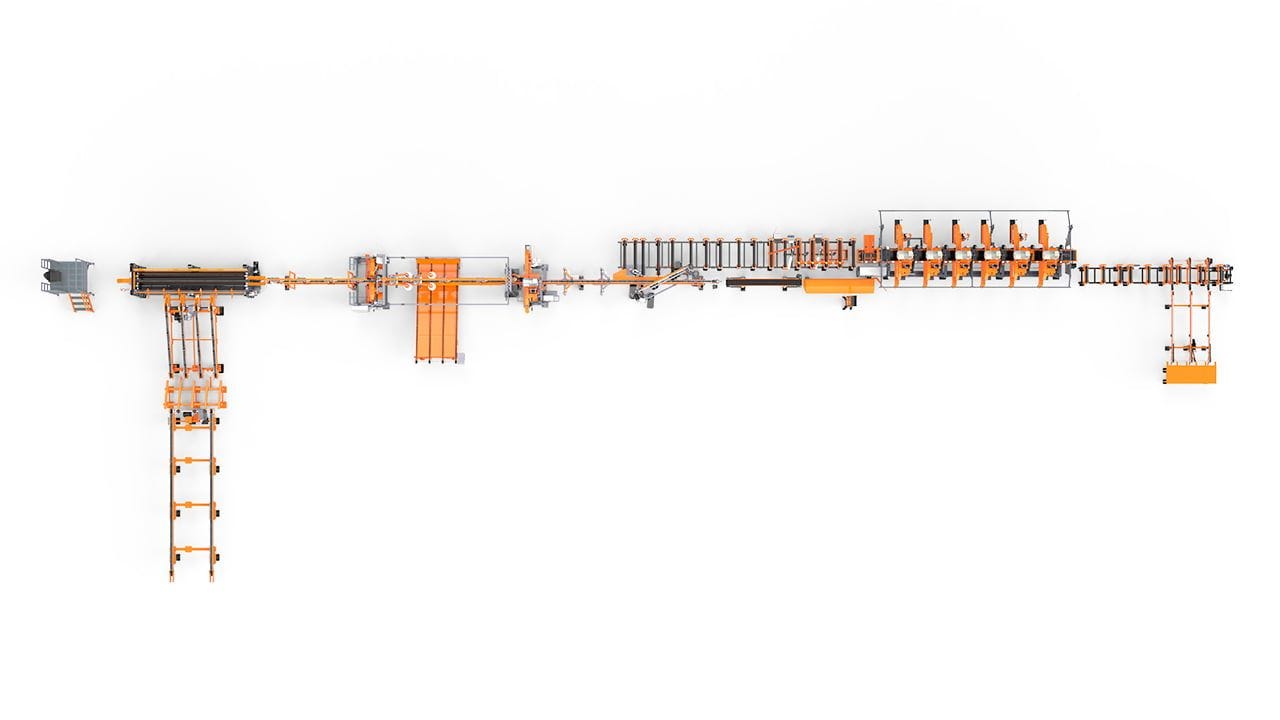

Offering more automation and features to reduce production costs, the SLP2 is the next stage in increasing profits from small- to medium-sized logs up to 400 mm (15.748″) in diameter.

The line can be configured in different ways depending on product requirements and budget. As few as two or three workers can successfully manage the whole line due to its level of automation. A centralised control console positioned at the front of the line gives the main operator a full view of the work, and puts all machine controls within easy reach.

The SLP2 is the ultimate solution for decreasing costs and increasing profits by automating your timber processing.

SLP1 Layouts

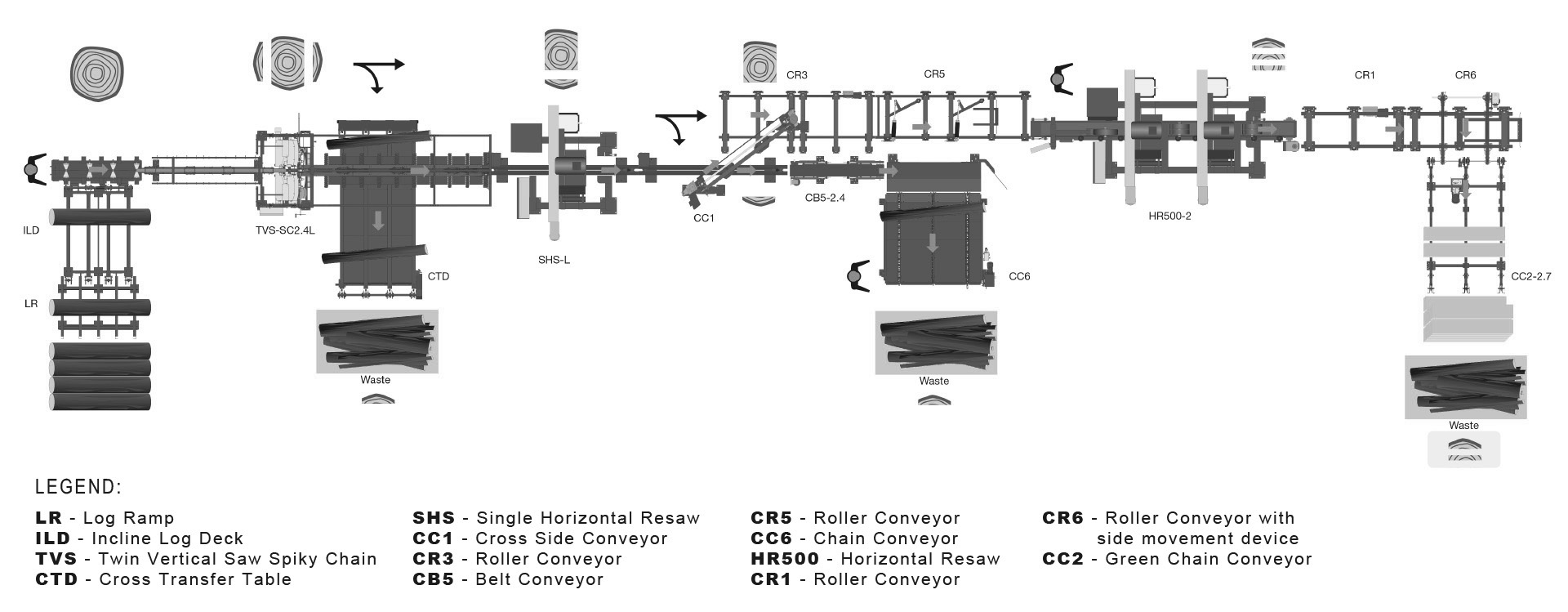

SYSTEM 1

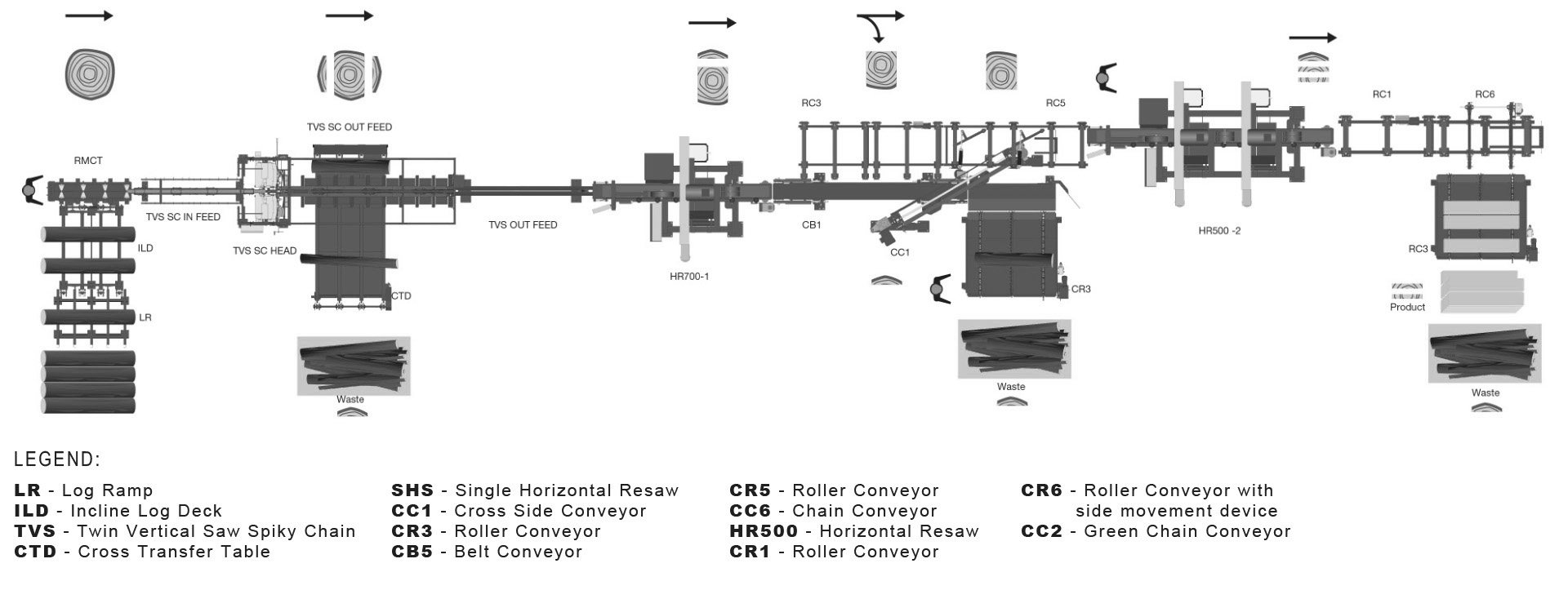

SYSTEM 2

Videos

Specifications

| POWER | |

|---|---|

| TVS-SC2.4L | 2 x 11 kW electric 2 x 7 kW electric |

| SHS | 11 kW electric 15 kW electric 18.5 kW electric |

| HR700 | 11 kW electric 15 kW electric 18.5 kW electric |

| Power supply | 400 V / 50 Hz, 3Ph |

| CUTTING CAPACITY | |

| Min. Log diameter | 150 mm |

| Max. Log diameter | 400 mm |

| Min. Log length | 1.2 – 2.4 m |

| Max. Log length | 2.4-3.6 m |

| Min. Cut width | 70 mm |

| Max. Cut width | 250 mm |

| SAWMILL FEATURES & OPTIONS | |

| Standard equipment | TVS – Twin Vertical Saw SVS – Single Vertical Saw SHS – Single Head Saw HR500 or HR700 – MultiHead Resaw |

| Optional support equipment | Loading: Log ramp, Log deck, Log incline deck Conveyors: Transfer deck, Roller tables Automated Log Turner |

| BLADE (LENGTH & WIDTH) | |

| TVS-SC2.4L | 4.67 m x 32-38 mm |

| SHS | 4.67 m x 32-38 mm |

| HR500 | 4.01 m x 32-38 mm |

| HR700 | 4.67 m x 32-38 mm |

| SAWMILL DIMENSIONS & REQUIREMENTS | |

| Length | 28 m |

| Width | 8 m |

| Height | 2.15 m |

Reviews

There are no reviews yet.