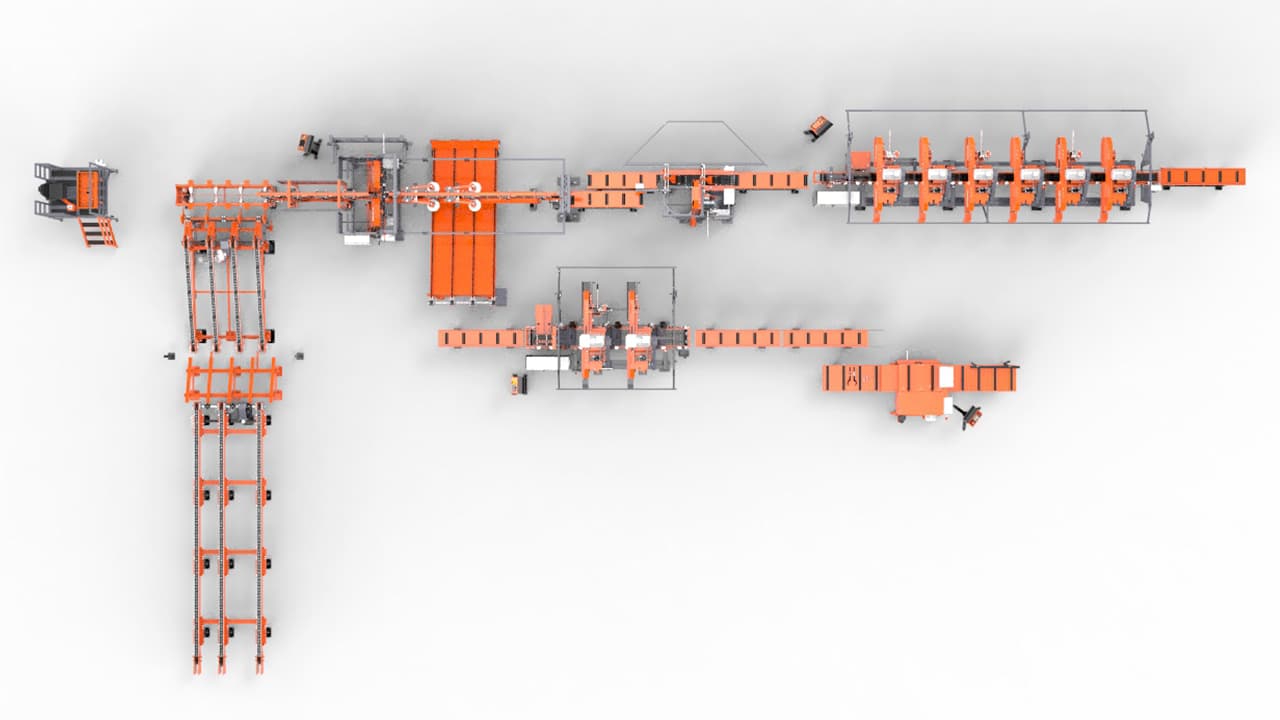

System SLP1

The profitable conversion of small logs

The SLP (Smart Log Processing) line uses thin-kerf blades on each sawmill unit in the line to deliver better log yield than other processing methods. Because the line is modular, machines in the line can be arranged to suit cutting needs as the market changes.

Доступно за замовленням, від:

Доступно за замовленням, від:

81,134 €

Highly popular among pallet manufacturers, the SLP1 specialises in making the most profit possible from low value logs up to 400 mm in diameter and increasing your competitive edge. The SLP1 line has been successfully used in sawing high quality construction grade timber to pallet material. It is a diverse line that can be adapted to many different configuration requirements to suit the sawmillers needs.

Because the line is modular, machines in the line can be arranged to suit cutting needs as the market changes. The SLP1 line utilises Wood-Mizer’s modular system, with many of the machines using the same electrical parts, belts, and bearings, requiring the sawmiller to keep fewer spares on hand.

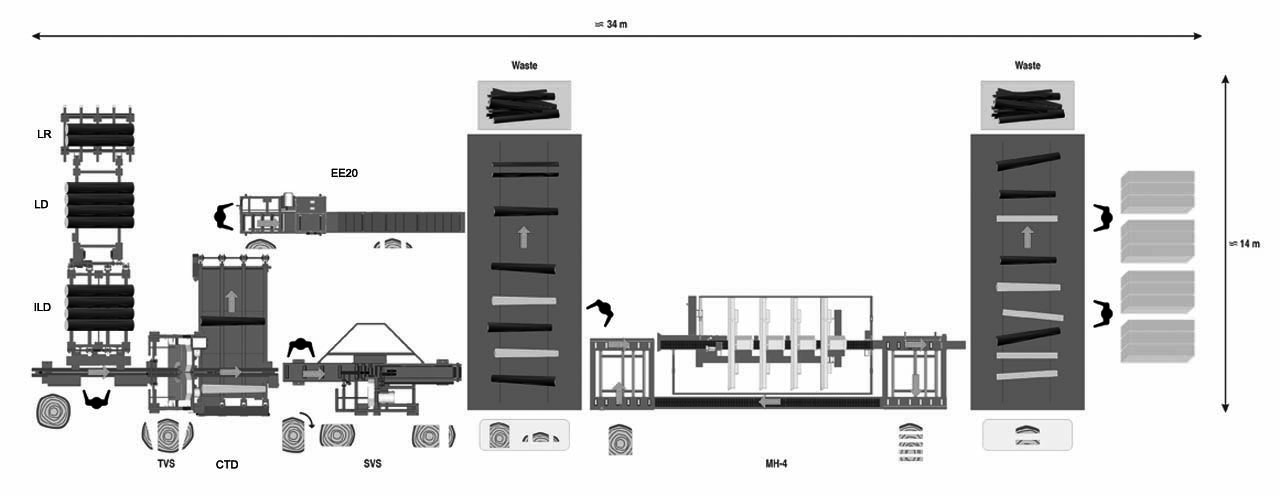

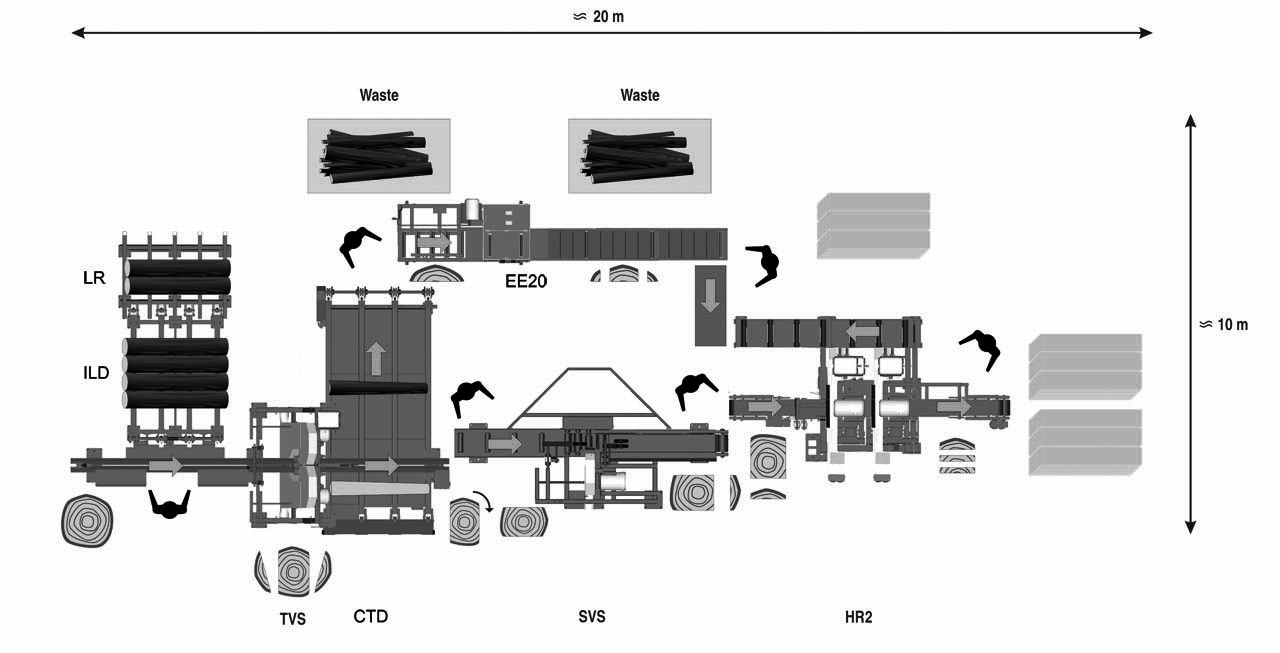

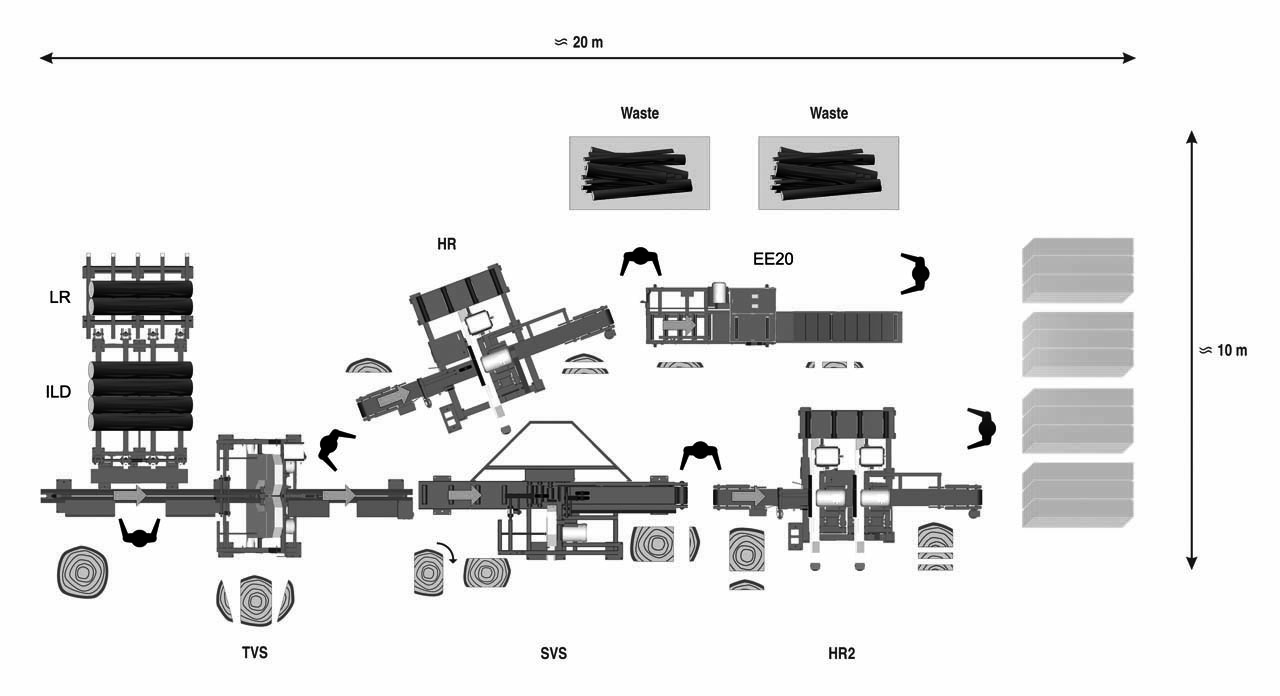

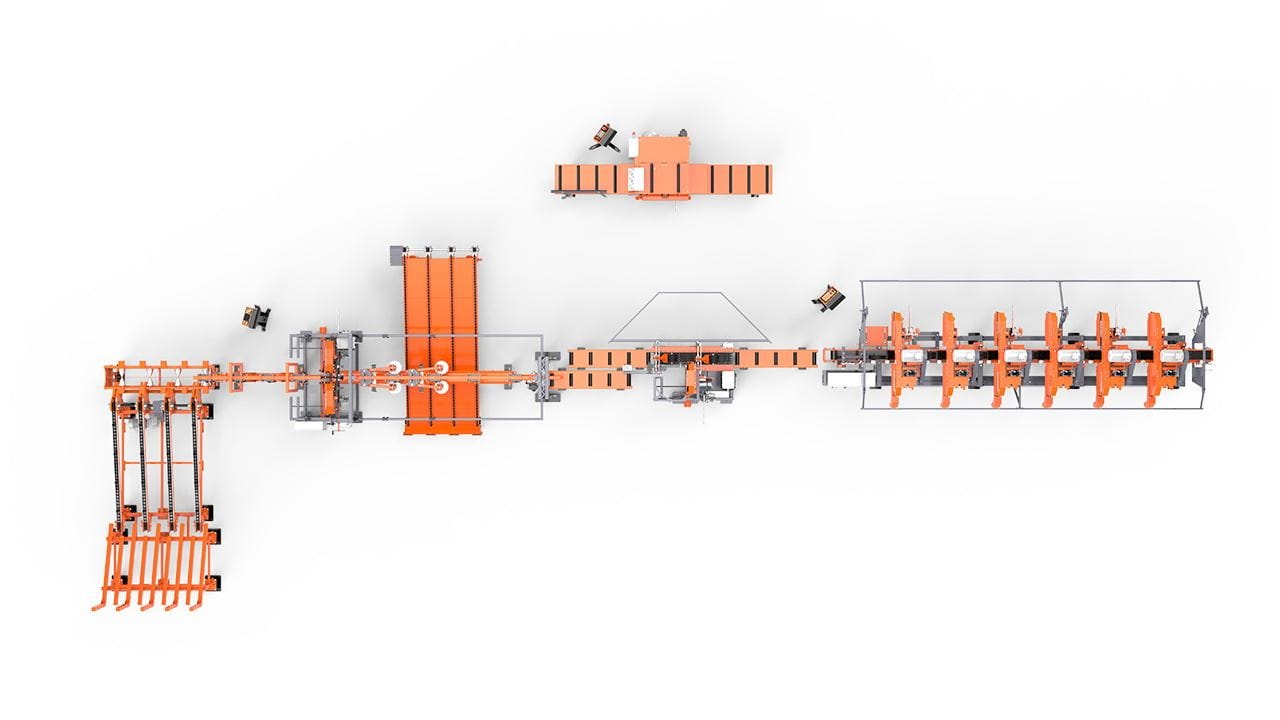

SLP1 Layouts

SYSTEM 1

SYSTEM 2

SYSTEM 3

SYSTEM 4

Videos

Specifications

| POWER | |

|---|---|

| TVS-SC2.4L | 2 x 11 kW electric |

| HR200 | 15 kW electric |

| HR500 | 2 x 11 kW electric |

| HR700 | 2 x 15 kW electric |

| Power supply | 400V / 50 Hz, 3Ph |

| CUTTING CAPACITY | |

| Min. Log diameter | 100 mm |

| Max. Log diameter | 400 mm |

| Min. Log length | 1.2 mm |

| Max. Log length | 2.4-3.6 m |

| Min. Cut width | 70 mm |

| Max. Cut width | 250 mm |

| SAWMILL HEAD FEATURES & OPTIONS | |

| Standard equipment | TVS – Twin Vertical Saw SVS – Single Vertical Saw HR500 or HR700 – MultiHead resaw |

| Optional support equipment | Loading: Log ramp, Log deck, Log incline deck Conveyors: Transfer deck, Roller tables |

| BLADE (LENGTH & WIDTH) | |

| TVS-SC2.4L | 4.67 m x 32-38 mm |

| HR200 | 4.01 m x 32-38 mm |

| HR500 | 4.01 m x 32-38 мм |

| HR700 | 4.67 m x 32-38 mm |

| SAWMILL DIMENSIONS & REQUIREMENTS | |

| Length | 28 m |

| Width | 8 m |

| Height | 2.15 m |

Reviews

There are no reviews yet.