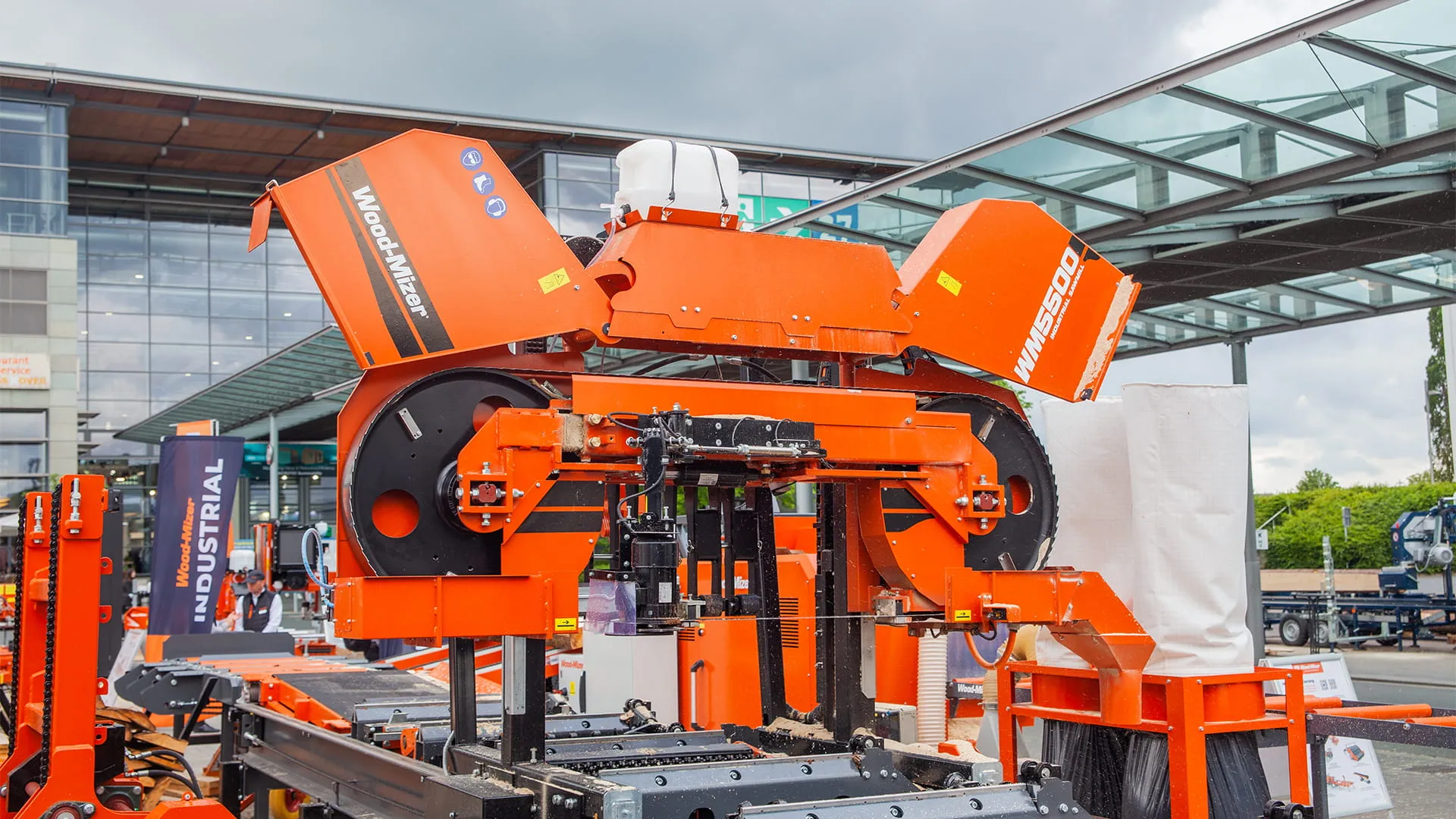

WM5500 Industrial Sawmill

Next-Generation Wideband Performance for Industrial Sawmilling

The Wood-Mizer WM5500 is a state-of-the-art industrial sawmill, engineered as the advanced successor to the renowned WB2000. Designed for maximum productivity and versatility, the WM5500 combines increased cutting capacity, flexible blade options, and cutting-edge technology to meet the demands of modern sawmilling operations.

The WM5500 can process logs up to 1 meter in diameter and is compatible with wide blades up to 120 mm, including Stellite-tipped options for superior cutting speed and finish. The sawhead supports 900 mm cutting width and height, with bed length configurations from 4.5 m up to 12 m to suit a variety of log sizes.

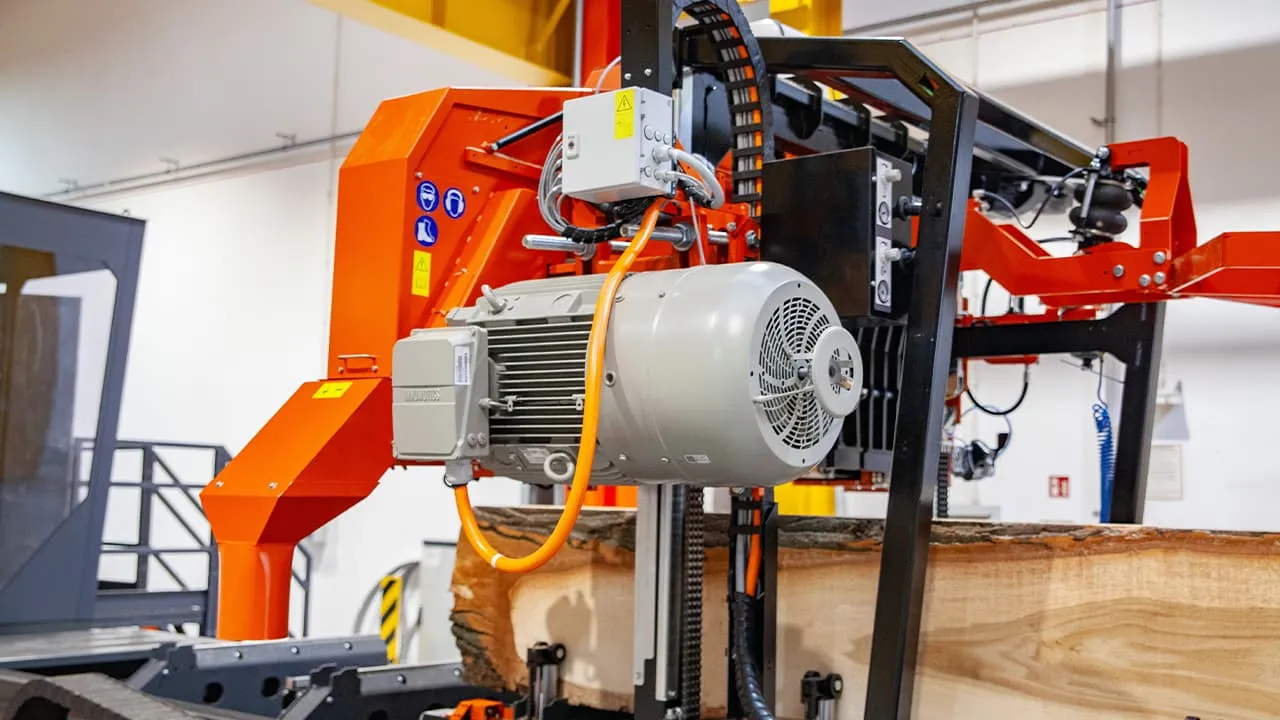

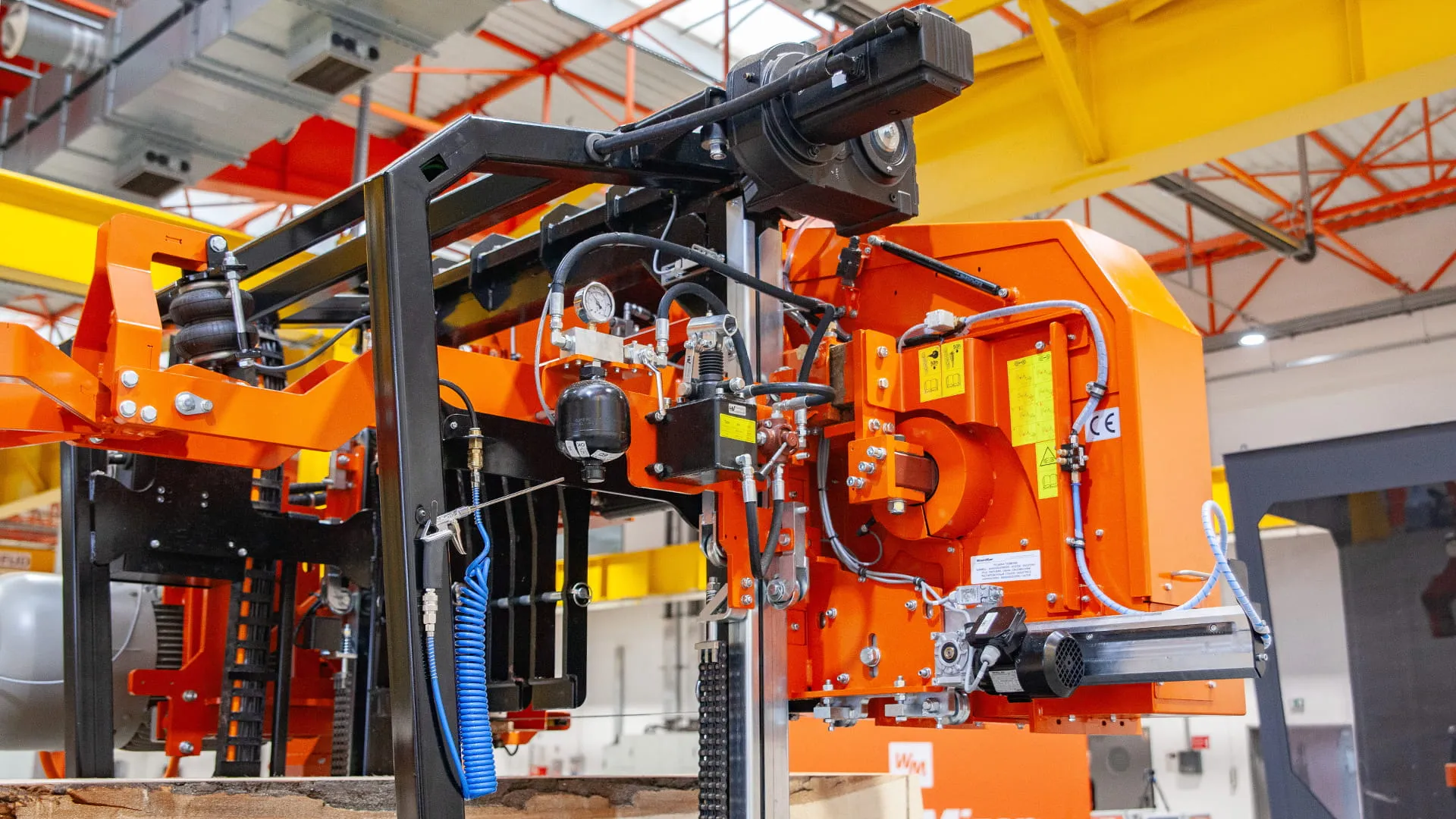

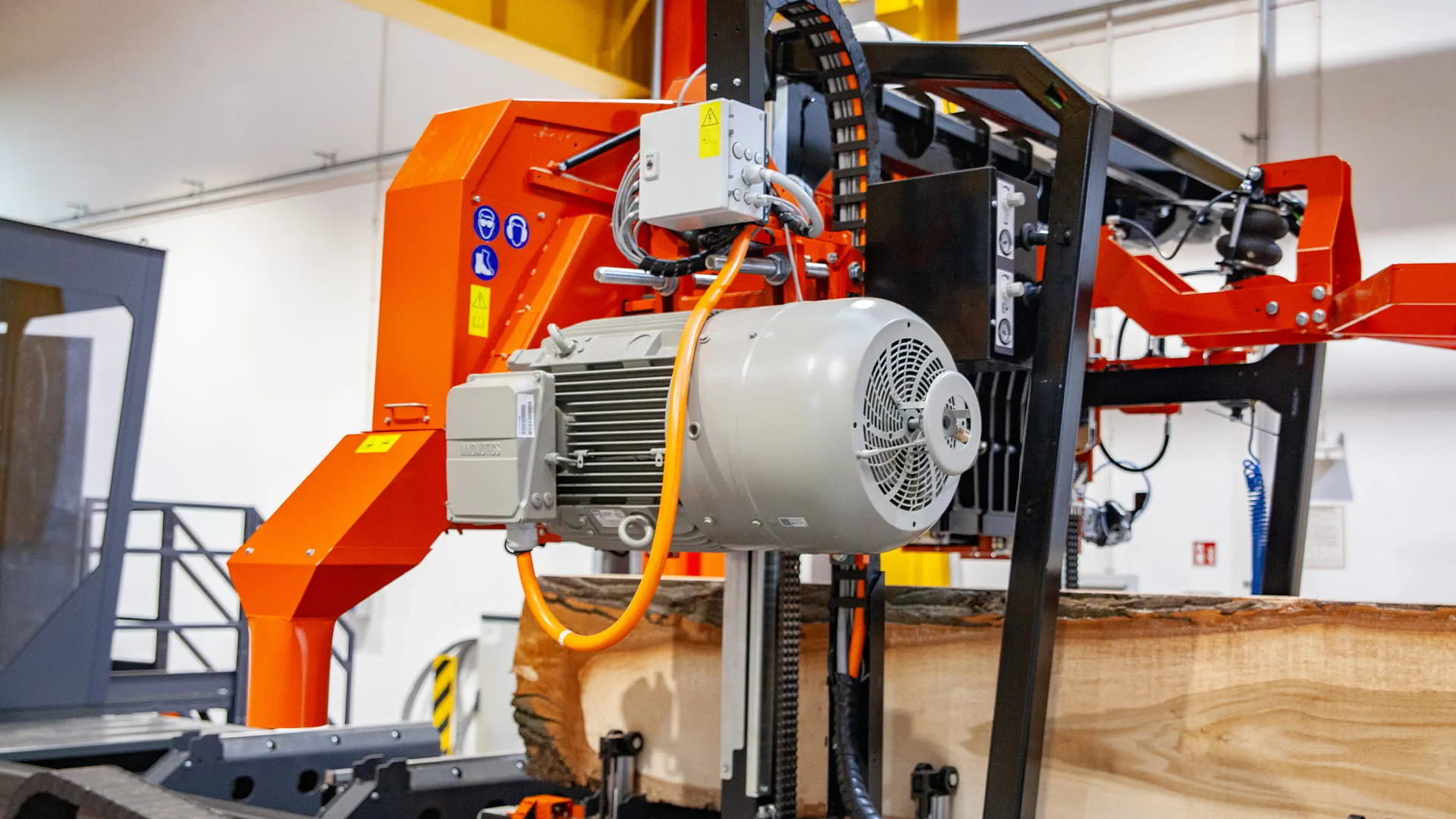

Key upgrades include a high-speed servo-driven head positioning system that halves the sawhead up/down movement time to just 5 seconds. A robust triple-row chain provides extra stability for moving the sawhead, while the new compressed-air blade lubrication system ensures consistent performance, especially for wider blades. The 45 kW motor provides additional power ideal for high-efficiency Stellite blades.

The WM5500 introduces customizable blade width options. Customers select their preferred blade width during ordering, which determines the configuration of blade wheels, guides, and wheel alignment. The advanced blade tensioning system can also be equipped with an electric pump for easier control from the operator cabin.

The redesigned operator cabin enhances ergonomics and functionality with an intuitive control interface, slanted monitors, joysticks, and an optional air-conditioning unit. Hydraulic operations have also been improved—faster for log loading, yet easily slowed for precision handling—thanks to a new bypass-based oil flow system.

The debarker and board removal system is now pneumatically controlled, offering smoother operation and easier maintenance. With an air gun included for cleaning the sawhead area, every detail has been considered to optimize performance and operator comfort.

From its powerful motor and wider blades to its upgraded electronics and control systems, the WM5500 delivers everything industrial sawyers need to boost efficiency, accuracy, and output.

Features

Compatible with Wide Blades

Use the Stellite 120 mm wide blades for top performance in milling various kinds of wood. Add 10-15% increase in efficiency in comparison to standard steel blades

Switch Blade Wheels

Run various blade widths – 50/75/100 or 120 mm – with replaceable blade wheels to add maximum flexibility in operation

Servo Motors for Up/Down

Move and position the sawhead with reduced time (4-5 seconds)

Compressed Air Assistance

Air pressure is used to operate the board removal system, debarker, and cleaning utility

Efficient Blade Lubrication

Lubricate and clean the blade with the help of compressed air for efficient distribution of the lubricant

Main Motor with Encoder

Use a strong 45 kW (60 HP) electric motor with an encoder/altivar to adjust the power, depending on cutting conditions

Effective Control of Hydraulics

Use a hydraulic setup with a bypass to limit the oil flow – faster for log loading and slower for log positioning

Comfortable Operator Cabin

Operator station complete with a seat, control and video monitors, joysticks and optional air conditioning, and thermal insulation

Videos

Specifications

| POWER SELECTIONS | |

|---|---|

| Power Selections | 30kW (40HP) electric 37kW (50HP) electric 45kW (60HP) electric |

| CUTTING CAPACITIES | |

| Max Log Diameter | 100 cm |

| Max Width of Cut | 90 cm |

| Max Log Length | 4.5 m (bed S size) 7.5 m (bed M size) up to 12 m (custom) |

| Min Log Length | 1,2 m |

| Min Log Diameter | 20 cm |

| Log Weight | 8 t |

| BLADE | |

| Blade Length | 6 200 mm |

| Blade Guides Style | Block Guides |

| Blade Lubrication System | Automatic Blade Oil Lubrication with Pneumatic Assistance |

| Blade Tension System | Electric Hydraulic Tension System with a Pressure Accumulator |

| Blade Wheel Type | Crowned Steel Wheels Special Blade Wheels depending on blade width |

| Blade Width | 50 mm (2″) 75 mm (3″) 100 mm (4″) 120 mm (5″) |

| HEAD FEATURES & OPTIONS | |

| Laser | Optional Laser |

| Board Removal | Board Return System with Pneumatic Assistance |

| Log Debarking | Debarker with Pneumatic Assistance |

| Blade Guide Arm | Controlled with Joystick |

| Blade Engagement | Controlled with Joystick |

| Head Forward/Reverse | Variable Speed Power Feed |

| Konfiguracja automatyczna | system powrotu deski z podparciem pneumatycznym |

| Setworks | PLC Industrial Setworks |

| Operator Location | Standing Platform with Operator Controls (EC) Platform with operator’s seat and joysticks system (PRO) Air-conditioned Cabin |

| Head Feed Speed (Forward) | Max. feed speed 50 m/min for cutting |

| Head Feed Speed (Reverse) | 80 m/min (260ft/min) |

| Observation Cameras | 4 Cameras standard |

| BED FEATURES & LOG HANDLING | |

| Side Supports | 2 – 8 Vertical Side Supports depending on the bed length |

| Hydraulic Speed | Variable speed control with foot pedal |

| Board Removal Conveyor | Board Removal Conveyor (Optional) |

| Hydraulic Output | 18LPM (4.8GPM) 27LPM (7.1GPM) 55LPM (14.5GPM) |

| Cant hold-down clamps | 2 or more Cant Hold-Down Clamps (Optional) |

| Log Leveling | 2 or more Powered Leveling Rollers |

| Log Turning | 1 – 3 Bi-directional Chain Turners |

| Log Loading | Log Deck (LD2) |

| Log Clamping | 1 Hydraulic Log Clamp |

| MACHINE DIMENSIONS & REQUIREMENTS | |

| Delivery Methods | Container or truck |

| Bed Construction | Twin Rail |

Reviews

There are no reviews yet.