Planer/Moulder MP260

Compact and versatile four-sided planer / moulder

Four-sided Moulder and Planer for full flexibility to produce finished timber.

Доступно за замовленням, від:

Доступно за замовленням, від:

Original price was: 15,870 €.13,381 €Current price is: 13,381 €.

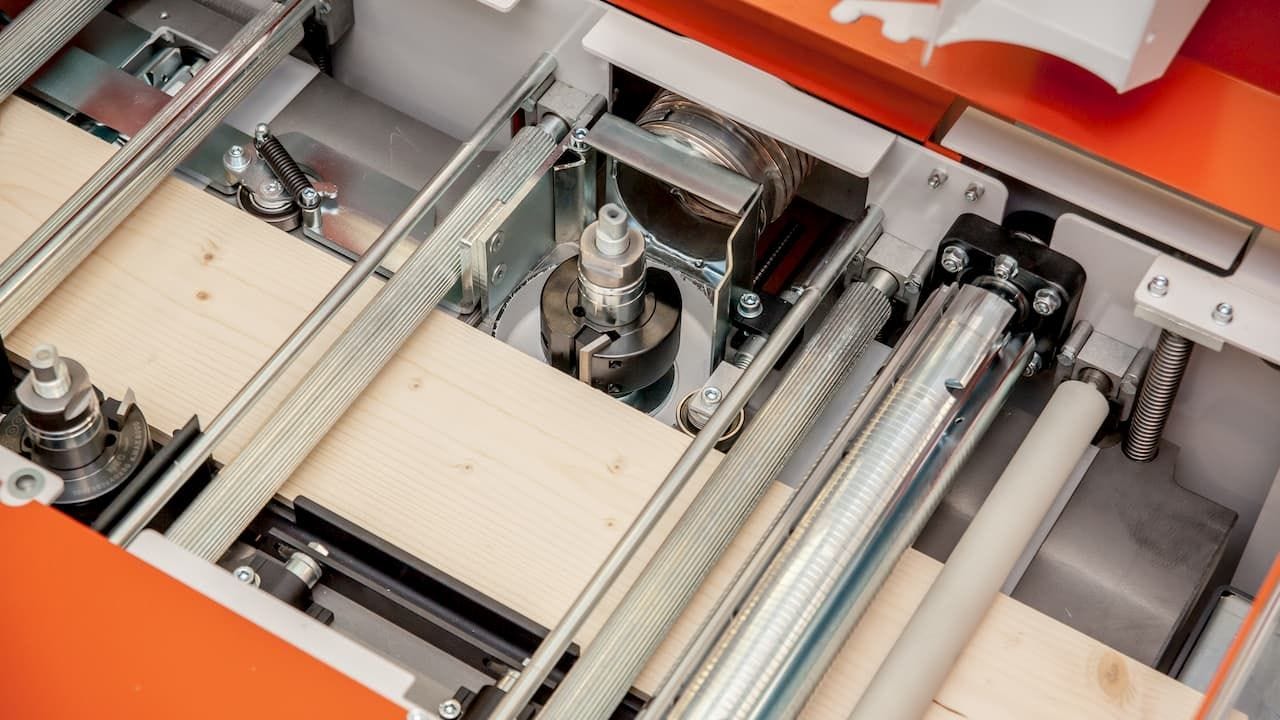

The MP260 four-sided planer / moulder is a versatile, compact machine engineered for professional woodworkers, carpenters, or joiners in the construction trade. Affordable and easy to use, the MP260 planes and moulds boards on all four sides in a single pass into a variety of professionally finished products including flooring, planed boards, crown moulding, cabinet trim, paneling, door and window frames, and furniture components.

Features

Centralized Control Panel

Allows the operator to start/stop all 4 cutter and power feed motors separately

Easy-to-change Knife Profiles

Changing knives is simple and takes approximately 10 to 20 minutes

Variable Feed Rate

Is adjustable from 2.5-14 m/min for 60 Hz

Adjustable Table Height

The table height is easily adjusted with a manual hand crank

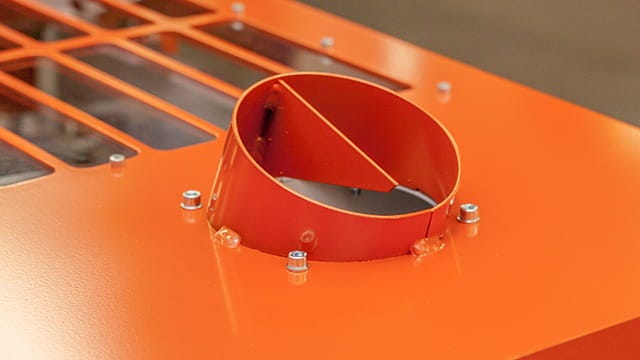

Multiple Extraction Points

Located near the cutters connect with your chip extraction system to keep chips from building up in the machine

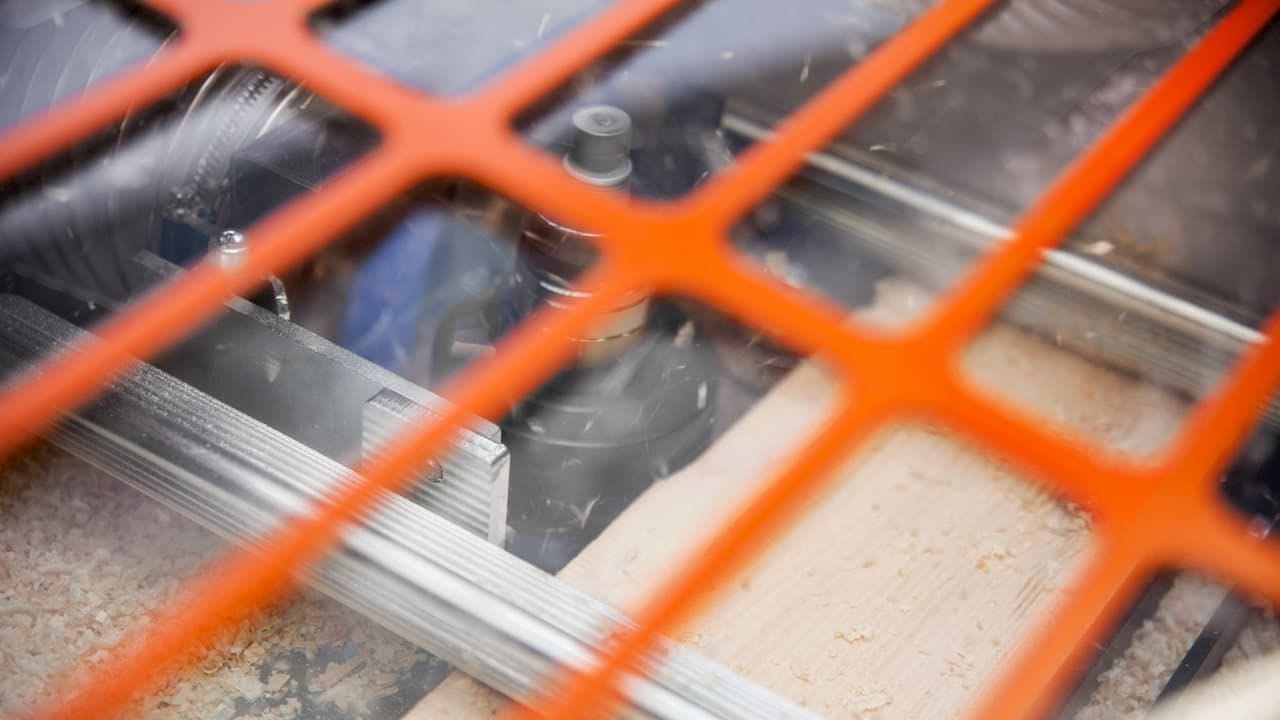

Large Viewing Window

Allows supervision of the entire cutting process from rough sawn boards to final products

Videos

Specifications

| 4-SIDED MOULDING CAPACITY | |

|---|---|

| Max. Width | 260 mm |

| Max. Height | 100 mm |

| 2-SIDED MOULDING CAPACITY | |

| Max. Width | 300 mm |

| Max. Height | 10 – 230 mm |

| 1-SIDED MOULDING OR THICKNESSING CAPACITY | |

| Max. Height | 410 mm |

| Height | 230 mm |

| FEATURES & OPTIONS | |

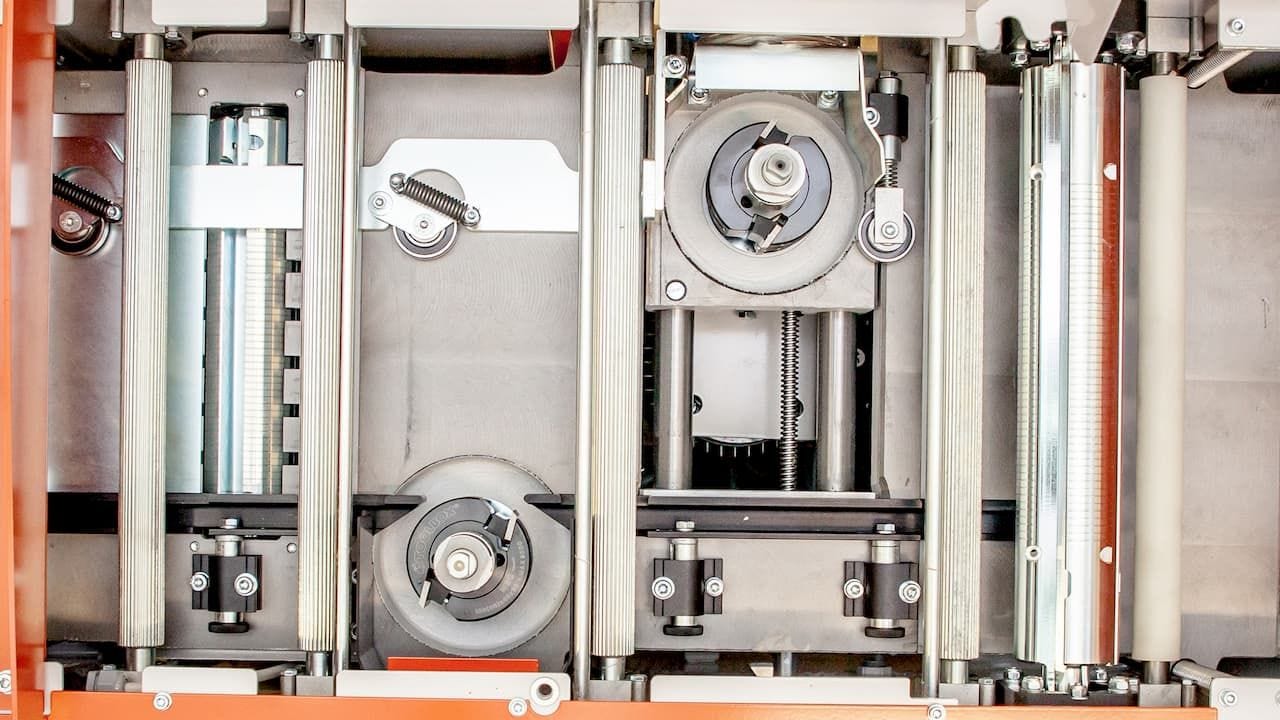

| Number of Horizontal Cutters | 2 |

| Number of Spindles | 2 |

| Number of Sawdust Extraction Ports | 4 |

| Viewing Window | Yes |

| Options | Infeed / Outfeed Tables – 1.2 m each Transport wheels |

| UPPER HORIZONTAL CUTTER | |

| Diameter | 72 mm |

| Width | 410 mm |

| Power | 4 kW (5.5 HP) |

| Rotation Speed | 6000 RPM / 50 Hz |

| Max. Cutting Depth | 8 mm |

| Max. Profile Depth | 20 mm |

| LOWER HORIZONTAL CUTTER | |

| Diameter | 72 mm |

| Width | 300 mm |

| Power | 3 kW (4 HP) |

| Rotation Speed | 6000 RPM / 50 Hz |

| Max. Cutting Depth | 8 mm |

| Max. Profile Depth | 15 mm |

| VERTICAL CUTTERS | |

| Spindle Diameter | 30 mm |

| Max. Cutter Height | 100 mm |

| Max. Diameter | 140 mm |

| Power | 3 kW (4 HP) |

| Rotation Speed | 6000 RPM / 50Hz |

| Max. Cutting Depth | 30 mm |

| STANDARD VERTICAL CUTTERS INCLUDED | |

| Type | TB90 |

| Diameter | 90 mm |

| Height | 40 mm |

| Knife Type | HSS |

| Knife Width | 50 mm |

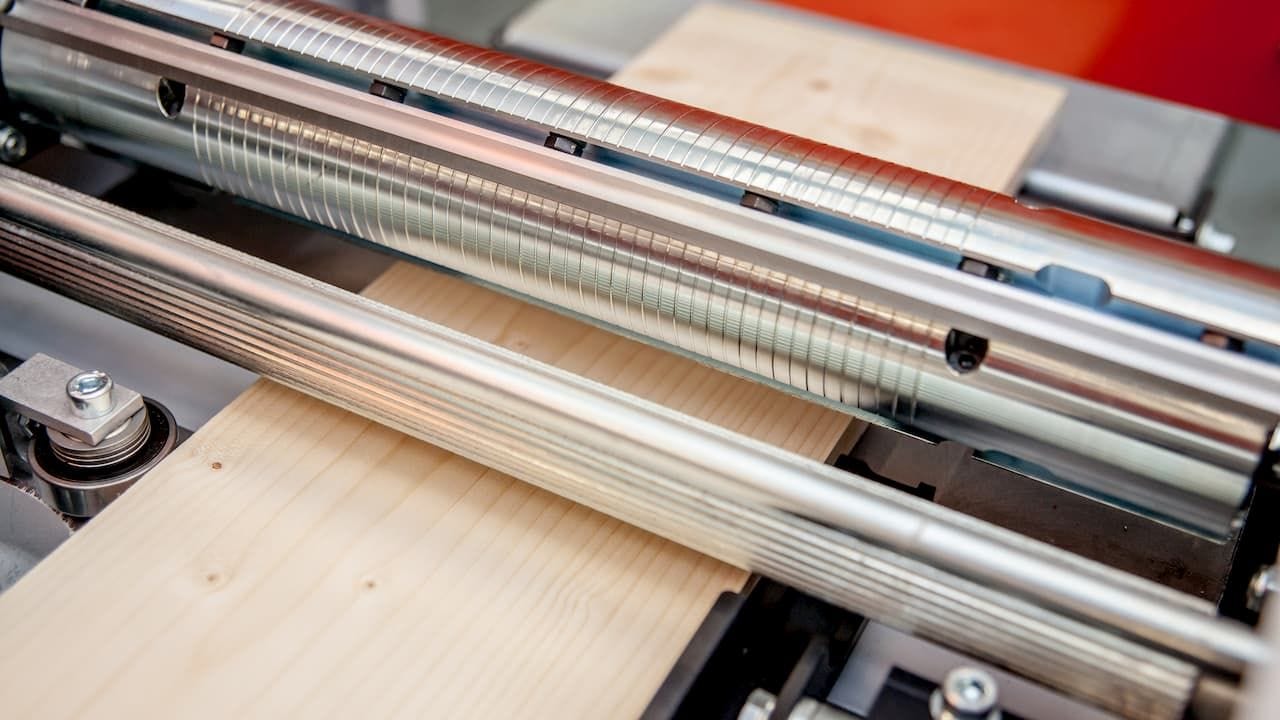

| POWER FEED | |

| Feed Motor | 0,37 kW |

| Feed Speed | 2 – 12 m/min / 50 Hz 2.5 – 14 m/min / 60 Hz |

| Feed Rollers | 4 Steel + 1 Polyurethane Rollers 5 Polyurethane Rollers (Optional) |

| DIMENSIONS & WEIGHT | |

| Length | 1100 mm |

| Width | 900 mm (35.4″) |

| Height | 970 mm |

| Weight | 410 kg |

| Shipment Weight | 495 kg |

| MACHINE STANDARDS & REQUIREMENTS | |

| Total Power | 13.4 kW (18 HP) |

| Electrical Requirements | 3-phase, 400-440 V, 16 A 3-phase, 230 V, 20 A 1-phase, 230 V, 32-50 A |

| Sawdust Collection Port Diameter | 3 x 100 mm + 1 x 125 mm |

| Safety Standards | CE |

Reviews

There are no reviews yet.