4-sided Planer / Moulder MP280

Second generation of planers/moulders based on the proven MP260 unit

The MP280 is a compact unit that combines the best features of the famous and proven MP360 and MP260 planers/moulders.

Доступно за замовленням, від:

Доступно за замовленням, від:

18,768 €

The MP280 planer/moulder makes a perfect solution for medium and large woodworking companies that want to supply their customers with premium wood products, such as floorboards, sidings, panels, door and window frames, decorative elements, and more.

The MP280 is equipped with an intuitive control panel with the switches engaging all motors and the feed mechanism separately, allowing for lower energy consumption and noise emission. The 13,78 kW electric motors drive the cutter heads at 6000 rpm, ensuring the best possible finish of the board surface.

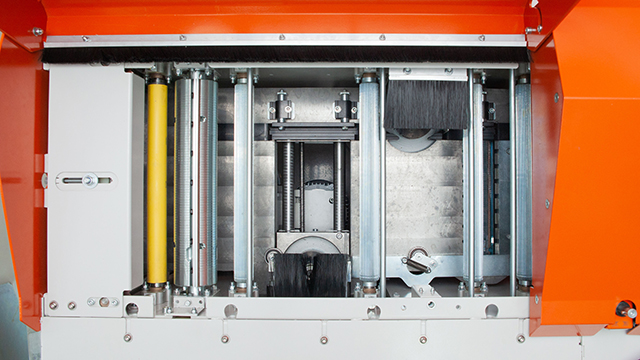

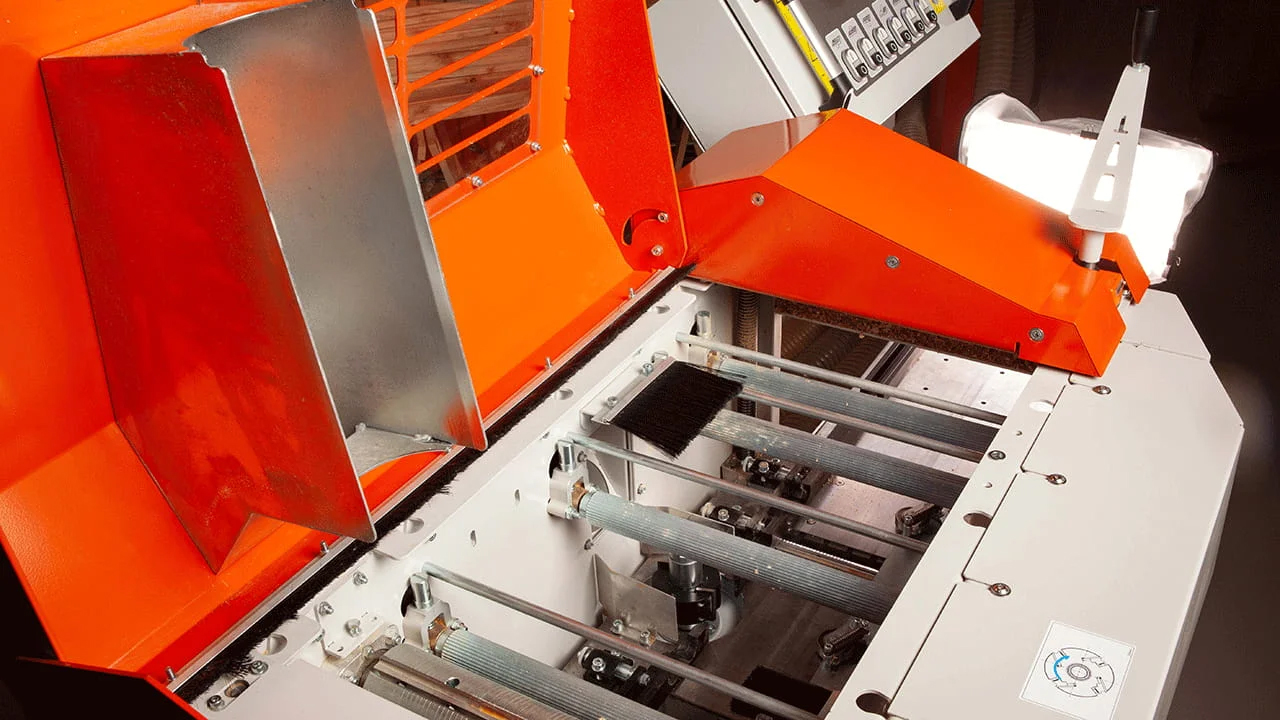

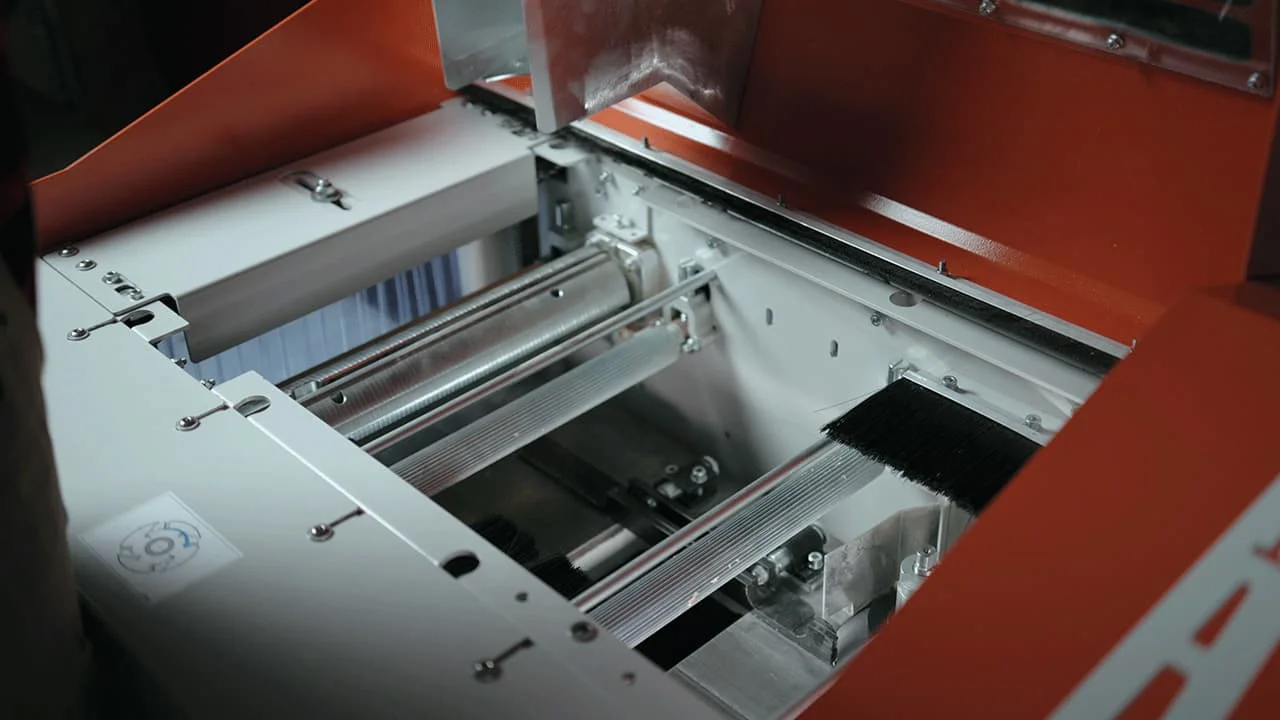

The MP280 features two horizontal cutter heads – the top shaft with a length of 410 mm and a diameter of 88 mm, while the bottom one 300 mm x 72 mm, and two side cutterheads (one in a fixed position and one moveable), which mould the material with a maximum height of 100 mm. Increased efficiency is possible due to 4-sided cutting in just one pass through the machine.

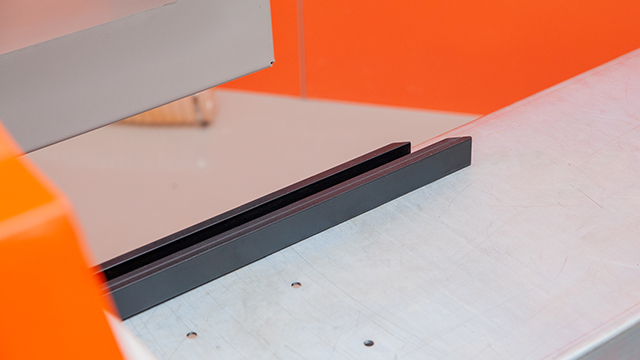

The feed mechanism has been incorporated from the bigger MP360 unit and comes with a variable speed of 3-15 m/min. The material feeds in and out of the machine on the 1,2m tables with protective steel curtains installed over the infeed entrance to prevent material throwback.

There are four sawdust exhaust ports – one with a diameter of 125 mm and three with 100 mm - and additional covers and brushes installed inside the machine to drive out the waste material from around the cutter heads as efficiently as possible. The MP280 planer/moulder is compatible with the Wood-Mizer MES dust extraction systems, which have been designed to keep the workplace clean and tidy.

Features

Operator panel

It allows for switching on/off all the cutterheads and motors individually

Easy adjustment

Ergonomic hand crank for adjusting the height of cast iron table

Easy replacing of knives

Replacing of knives isn’t complex and it takes up to 20 minutes

Extended guide bar

For easier feeding the material to the machine

Feed speed

Variable 3-15 m/min

Four cutterheads

Mould and plane four sides simultaneously

Gravity indicator

Shows the variable feed speed

Heavy-duty construction

Made of cast iron, robust steel frame and high quality components

Infeed and outfeed tables

Make feeding of the material easier

Sawdust extraction ports

The ports can be connected with the extraction system and will remove any sawdust from inside the machine

Top cover

The cover with a viewing window allows for a safe inspection of the woodworking machine

Width indicator

Allows for precise adjustment of the width in order to feed the materials of various dimensions

Videos

Specifications

| 4-SIDED MOULDING CAPACITY | |

|---|---|

| Max. Width | 250 mm |

| Max. Height | 100 mm |

| 2-SIDED MOULDING CAPACITY | |

| Max. Width | 300 mm |

| Max. Height | 230 mm |

| 1-SIDED MOULDING OR THICKNESSING CAPACITY | |

| Max. Width | 410 mm |

| Max. Height | 230 mm |

| UPPER HORIZONTAL CUTTER | |

| Diameter | 88 mm |

| Width | 410 mm |

| Power | 4 kW (5,5 HP) |

| Rotation Speed | 6000 RPM / 50 Hz |

| LOWER HORIZONTAL CUTTER | |

| Diameter | 72 mm |

| Width | 300 mm |

| Power | 3 kW (4 HP) |

| Rotation Speed | 6000 RPM / 50 Hz |

| VERTICAL CUTTERSE | |

| Spindle Diameter | 30 mm |

| Max. Cutter Height | 100 mm |

| Max. Diameter | 140 mm |

| Power | 3 kW (4 HP) |

| Rotation Speed | 6000 RPM / 50 Hz |

| POWER FEED | |

| Feed Motor | 0.37 kW (0.5 HP) |

| Feed Speed | 3 – 15 m/min / 50Hz |

Reviews

There are no reviews yet.