Planer/Thicknesser MP200

Plane and mould up to two sides at one time

With the MP200 Planer/Moulder, you can plane and mould on one or two sides at once to produce mouldings or flooring.

Доступно за замовленням, від:

Доступно за замовленням, від:

Original price was: 9,177 €.7,737 €Current price is: 7,737 €.

With the MP200 Planer/Moulder, you can plane and mould on one or two sides at once to produce mouldings or flooring. The MP200 includes 1 horizontal top cutter, and 1 vertical side cutter. Both can be fitted with planing knives or moulding profile knives.

You begin by planing or moulding one or two adjoining sides in one pass. The power feed rollers move the board under the horizontal cutter and past the vertical side cutter. If you are just planing, then you can simply flip the board over, adjust the table height, and then plane the final two sides.

If you are moulding a profile, then you simply need to change out the knives, adjust the table height and then mould the final two sides.

With the MP200, you can plane and mould timber in only two passes.

Features

Profile knives

Possibility of using profile knives on both cutterheads to make various shapes and profiles of final wood products

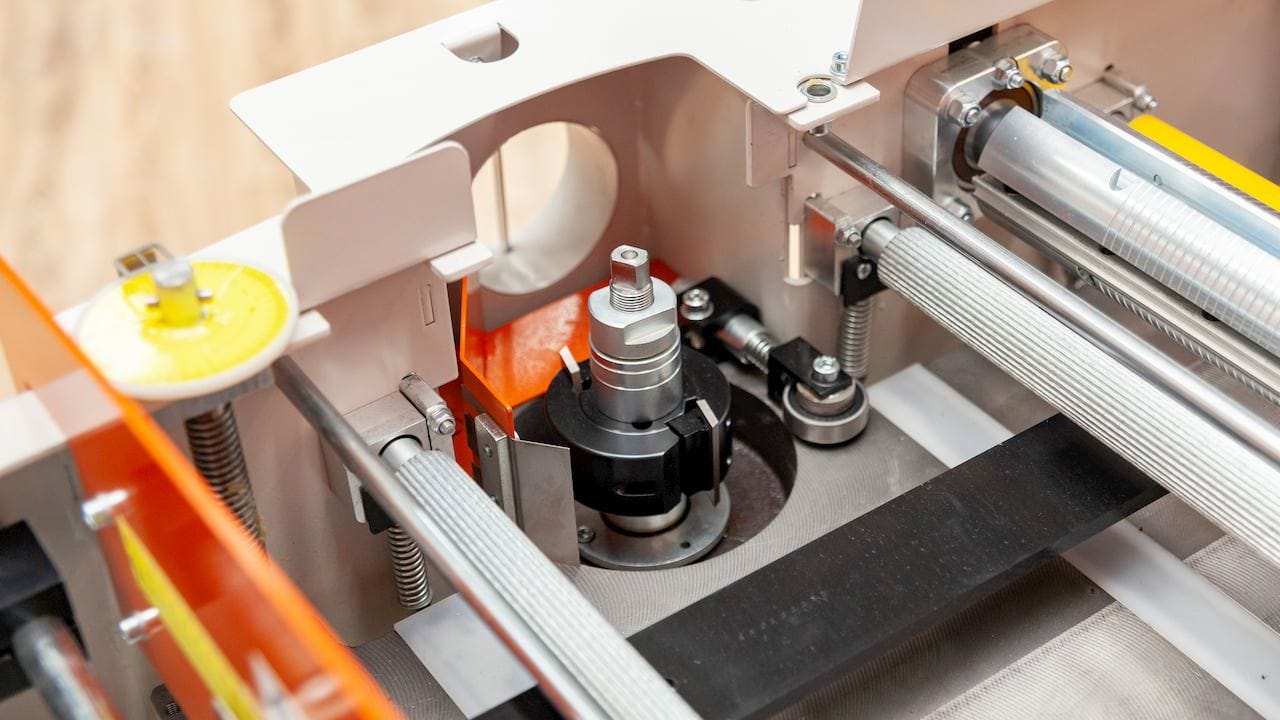

Side cutterhead

Easy and quick installation/deinstallation of the side cutterhead for saving time and increasing productivity

Power supply outlet

Power supply outlet on the electrical box already accommodated for plugging in the power. You can start working right after unboxing the machine

Height indicator

Clear indicator showing the height of the planing table, allowing for precise control of planing parameters

Height adjustment

Quick height adjustment of the planing table by turning a hand crank, allowing for comfortable changing of planing parameters

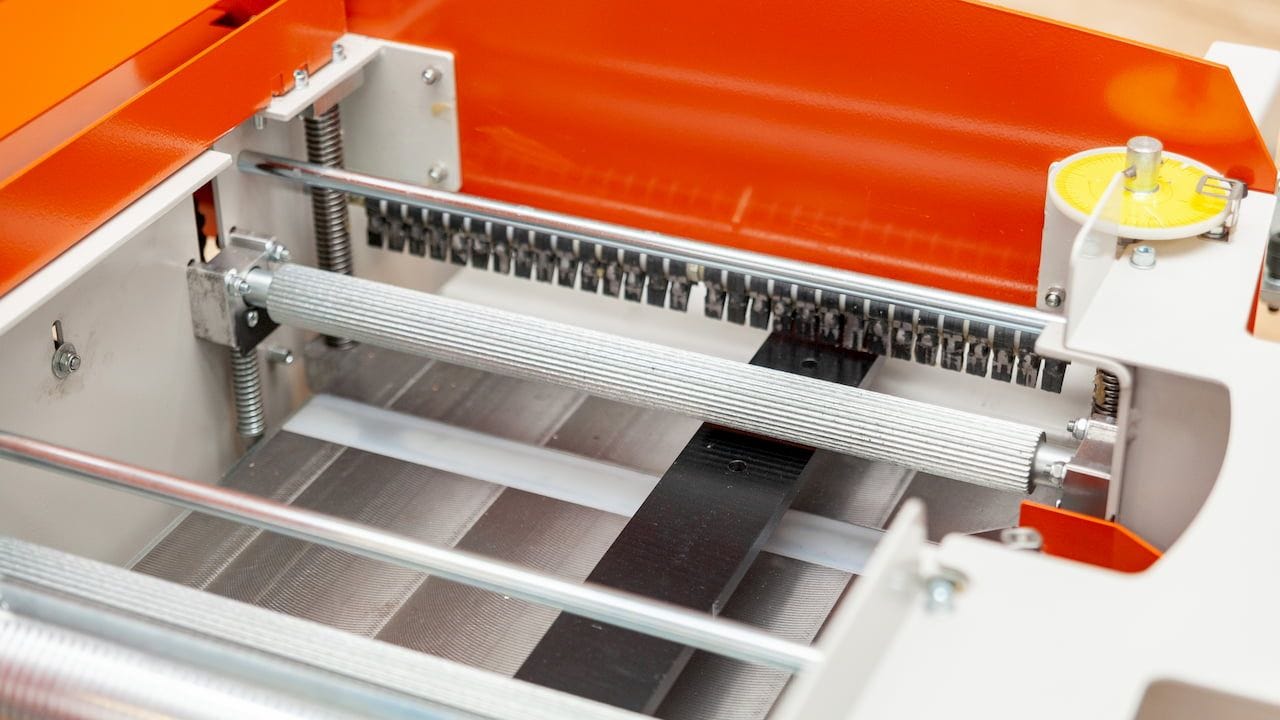

Assistant roller

Assistant roller on the infeed table optimizing the material feeding process

Infeed ledger with indicator

Adjustable infeed ledger with the indicator showing the material width

Extension table

Possibility of adding infeed or outfeed table by another 1,2 m long section

Caster wheels

Optional caster wheels with brakes for easy and quick transportation around the workshop

Variable feed speed

Optional variable feed speed of 2-12 m/min

Videos

Specifications

| HORIZONTAL CUTTER | |

|---|---|

| Motor | 3 kW (4 HP), 3-phase |

| Diameter | 72 mm |

| VERTICAL SPINDLE | |

| Motor | 3 kW (4 HP), 3-phase |

| Spindle Diameter | 30 mm |

| Tool Diameter | 140 mm |

| THICKNESSING | |

| Max. Height | 220 mm |

| Max. Width | 410 mm |

| Table Length | 830 mm |

| Max. Cutting Depth | 6 mm |

| MOULDING | |

| Max. Height | 100 mm |

| Max. Width | 310 mm |

| Max. Cutting Depth | 10 mm |

| FEED SYSTEM | |

| Feed Motor | 0.18 kW (0.25 HP), 3-phase 0.37 kW (0.5 HP), 3-phase (with planetary gearbox) |

| Feed Speed | 5 m/min 2-12 m/min (with planetary gearbox) |

| Feed Roller Diameter | 32 mm |

Reviews

There are no reviews yet.