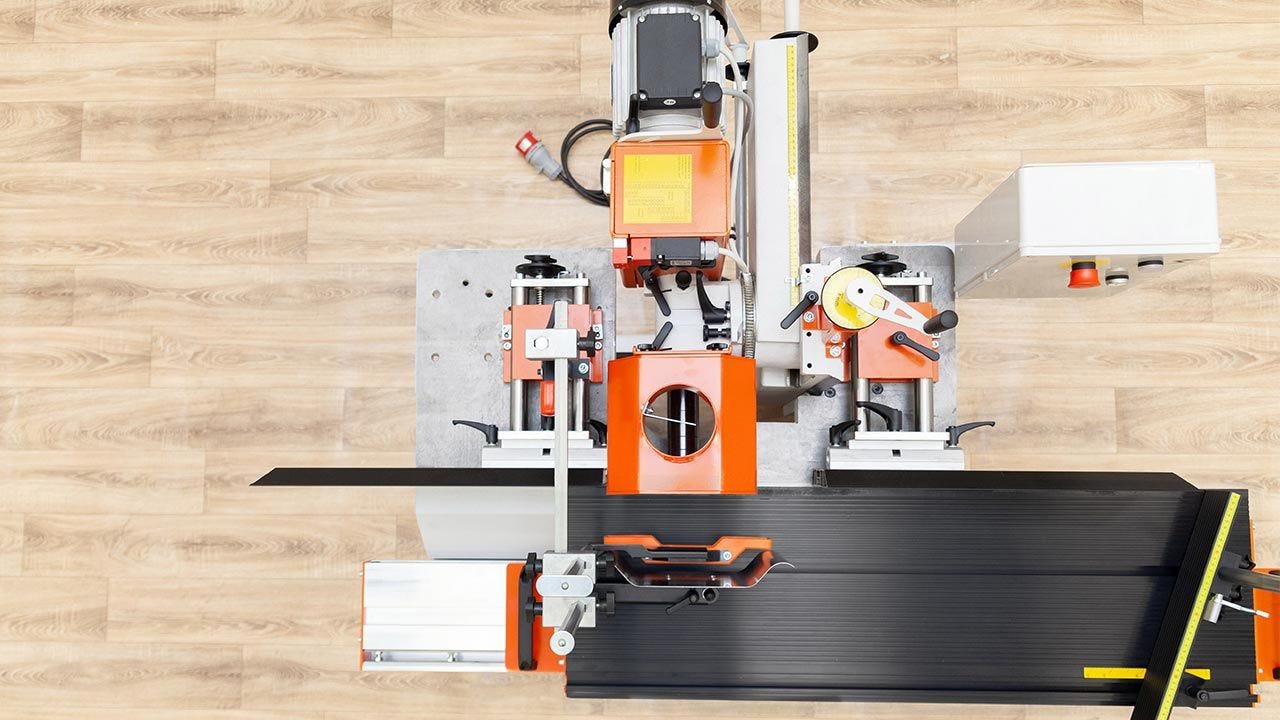

Vertical spindle moulder MF130

Ultimate flexibility to produce unique wood products

The MF130 is the answer when you need more flexibility to produce many varieties of unique products in your workshop.

Доступно за замовленням, від:

Доступно за замовленням, від:

10,902 €

The MF130 is the answer when you need more flexibility to produce many varieties of unique products in your workshop. Designed for ultimate versatility, you can use the MF130 for straight moulding, curved moulding, routering, tenoning and more!

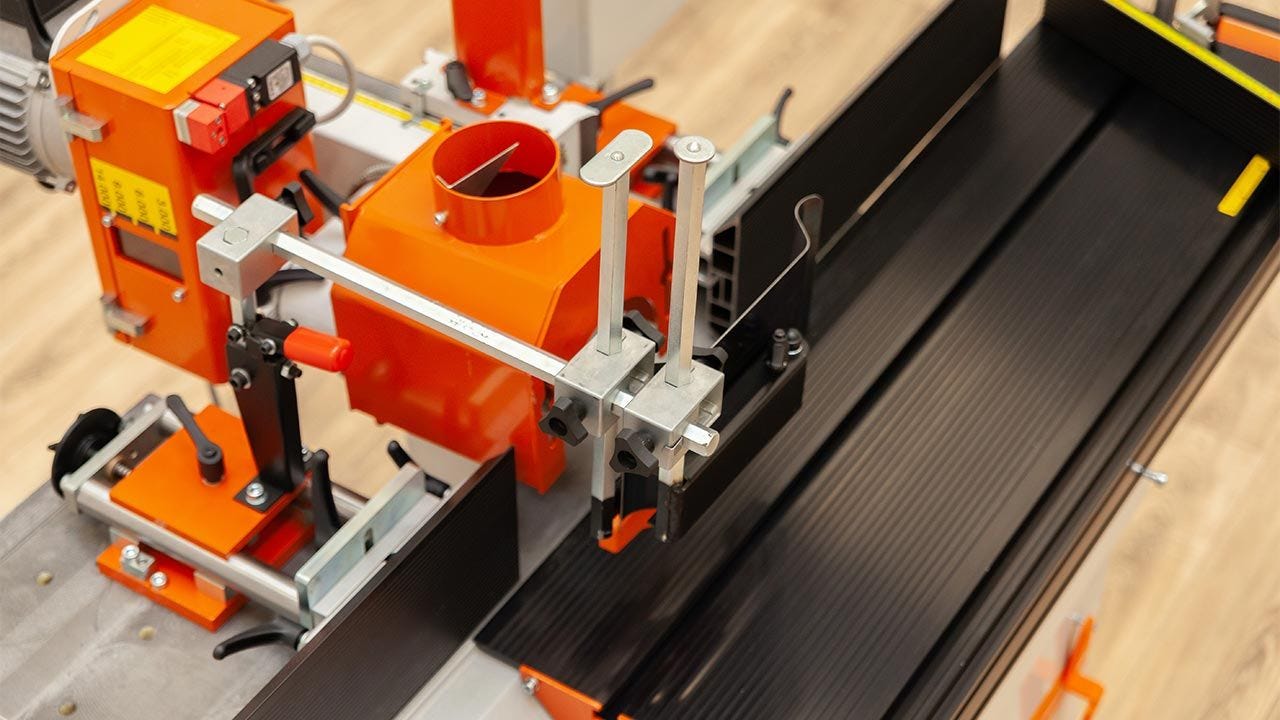

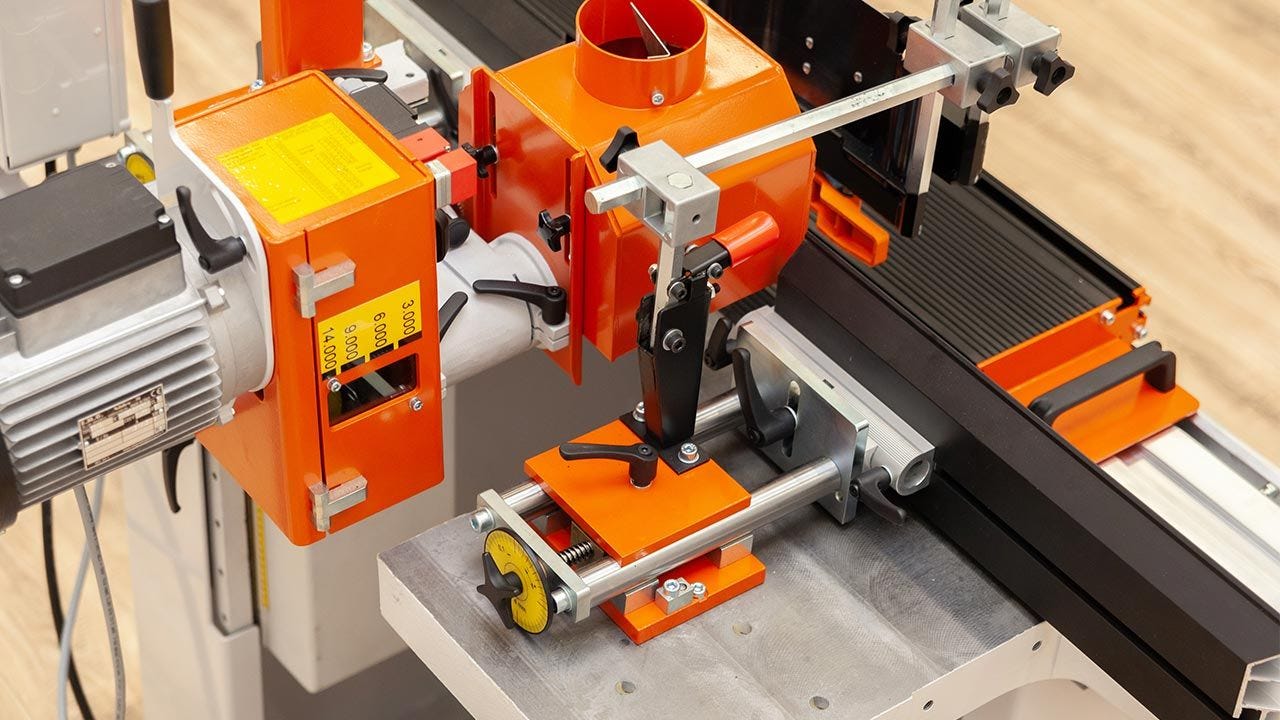

The spindle can be raised or lowered, and with a tiltable range of 270 degrees, the cutter or router bit can machine the board from below, the sides and from above – at almost any angle. You can mould one board on all four sides, as well as mould the ends of the board, and router holes into the surface – all with the MF130’s single spindle being uniquely configured for each operation.

Boards are passed through the machine with a sliding table, held down with included clamps, or they can be passed over the cutter manually. Additional options are available to expand the possibilities of the MF130 such as a multidirectional table, curved fences for making curved mouldings, and even a power feed.

When you need ultimate flexibility from one machine – the MF130 is the answer!

Videos

Specifications

| POWER | |

|---|---|

| Motor power | 3 kW (4 HP), 3-phase 400 V |

| MOVEMENTS SPINDLE | |

| Tilting | 270 deg |

| Vertically | 500 mm |

| Horizontally | 350 mm |

| TECHNICAL DATA | |

| Spindle diameter (standard) | 30 mm |

| Router spindle options | 6-20 mm |

| Max cutter diameter | 200 mm |

| Max cutter height | 130 mm |

| Spindle speeds | 3000, 6000, 9000 rpm |

| Router spindle speeds | 3000, 6000, 9000, 14000 rpm |

| Fence size | 152 mm |

| DIMENSIONS | |

| Sliding table length | 1100 mm |

| Sliding table width | 350 mm |

| Sliding length | 1087 mm |

| Table length | 900 mm |

| Table width total | 750 mm |

| Table height | 850 mm |

| Weight | 375 kg |

Reviews

There are no reviews yet.