Sawmill LT15CLASSIC

Compact, economical and reliable sawmilling solution

Popular for its quality, wide capabilities, and affordability, this sawmill does it all – from hobbyist to commercial work.

Доступно за замовленням, від:

Доступно за замовленням, від:

Original price was: 13,127 €.10,884 €Current price is: 10,884 €.

Incredibly versatile, the LT15 Classic sawmill is very popular because of its high quality, wide capabilities, proven reputation, and affordability. From enabling rural development, sawing multiple shifts commercially, to supplying quality lumber for the home hobbyist, this sawmill does it all.

The LT15 Classic cuts logs up to 70 cm in diameter and 5.4 m long with the standard bed options. In order to cut longer logs, bed extensions can be added to extend the sawmill bed to any required cutting length. Thin-kerf blades require minimal energy consumption, so smaller motors provide sufficient power to cut all wood types. Petrol and diesel engine options are available.

Logs are secured to the bed by the two standard log clamps and three adjustable backstops. Head height is precisely positioned by an electronic up/down motor. Cutting is accomplished by steadily advancing the sawmill head along the length of the log by turning a hand crank. Once the cut is completed, the head is pulled back and lowered into position for the next cut.

A water tank feeds lubrication directly to the blade to improve cutting performance and keep the blade clean. The adjustable blade guide arm keeps the blade well supported while cutting various sized material. Blade tension is easily adjusted, and keeps the blade at the proper tension for cutting. Wood-Mizer’s wide range of affordable blades can meet any cutting requirement, and deliver maximum log yield and minimal waste of the valuable timber.

Popular Options

Increase productivity with Setworks – simply select the board thickness required and the head height automatically positions for each cut. Increase production by adding power feed forward/reverse. A debarker, which prolongs blade life by clearing away dirt and rocks from the bark, can be added to AC models. Add the MP100 moulder/planer in order to produce finished beams and moulded columns.

Features

Sawmill Control Panel

Controls for the Head Up/Down and optional Power Feed and Optional Debarker are at the operator’s fingertips

Optional Electronic Setworks

Simply select the board thickness required and the head height automatically positions for each cut

Log clamps

Secure logs and allow you to cut as low as 25 mm from the bed

Plane and Mould Finished Beams

Saw logs and plane and mould finished beams by adding the MP100 Planer/Moulder to your LT15 sawmill

Thin-Kerf Wood-Mizer Blades

Cut hardwoods and softwoods with Wood-Mizer’s wide range of blades

Optional Power Feed

Increase production by adding power feed forward/reverse

Log Leveling Wedge

Level out tapered logs for sawing

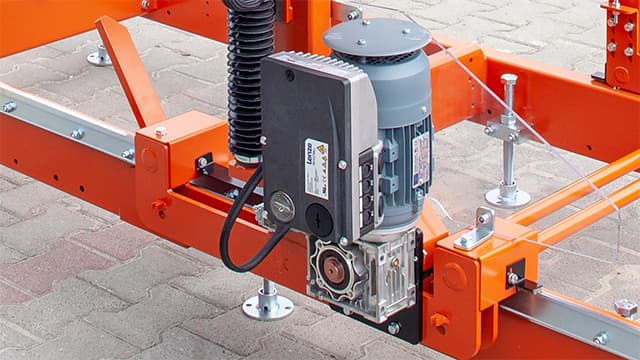

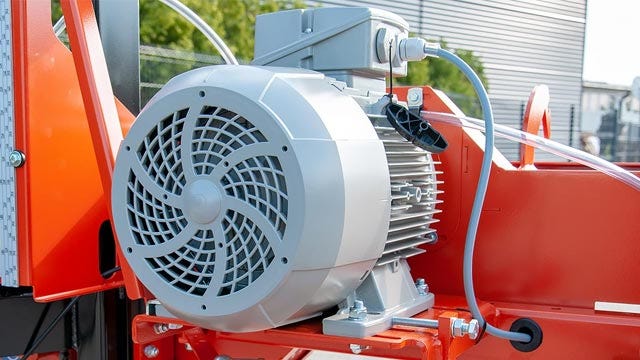

Electric Motor Options

Choose from several electric motors to meet your requirements

Videos

Specifications

| POWER | |

|---|---|

| Power | 7.5 kW Electric 11 kW (E15) Electric 19 HP Petrol 10 HP Diesel |

| CUTTING CAPACITY | |

| Max. Log Diameter | 70 cm |

| Max. Log Length | 5.2 m (2 segments 2.7 m each, M2 Bed) 5.4 m (3 segments 1.95 m each, S3 Bed) 7.9 m (3 segments 2.7 m each, M3 Bed) |

| Max. Width of Cut | 64 cm |

| Max. Cant Width |

59 cm |

| Max. Depth of Cut |

27 cm |

| HEAD FEATURES AND OPTIONS | |

| Setworks | SW10 (for AC models) |

| Head Up/Down | Electric (Screw) |

| Head Forward/Reverse |

Hand Crank Electric |

| Blade Guide Arm |

Manual |

| Blade Lubrication |

Electro Valve |

| Blade Tension System |

Screw with Gauge |

| Debarker |

Optional |

| Additional Options |

N/A |

| Sawdust Collection Port Diameter |

101.6 mm (4”) |

| BLADE | |

| Length | 4010 mm |

| Width | 32 mm 35 mm |

| BLADE WHEELS | |

| Diameter | 483 mm |

| Type | Belted |

| Blade Wheel Material | Cast Iron |

| BED FEATURES AND OPTIONS | |

| Bed Construction | Twin Rail |

| Angled Bed Rails | N/A |

| Bed Extensions |

Additional Bed Sections: 1.95 m or 2.7 m |

| Trailer Package |

N/A |

| LOG HANDLING | |

| Manual | S3 Bed (3 segments 1.95 m each): 6 Side Supports, 3 Manual Log Clamps M2 Bed (2 segments 2.7 m each): 4 Side Supports, 2 Manual Log Clamps Log wedge |

| STANDARD Hydraulic |

N/A |

| SUPER Hydraulic |

N/A |

| SAWMILL FEATURES AND OPTIONS | |

| Frame Construction | Semi-Cantilever |

| Power Requirements |

400 V / 16 A (7.5 kW) |

| Standards |

CE |

| Options |

Log Loading Ramps Cant Hook Log Moulder/Planer MP100 or MP150 |

Reviews

There are no reviews yet.