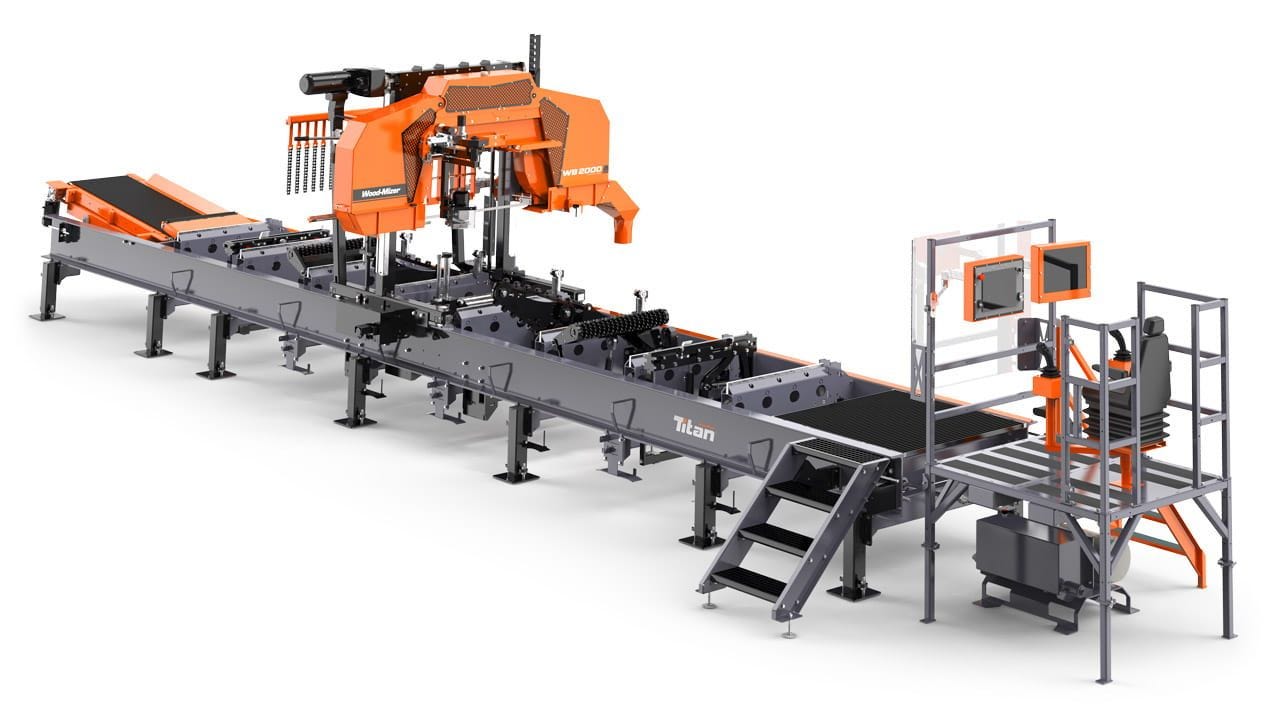

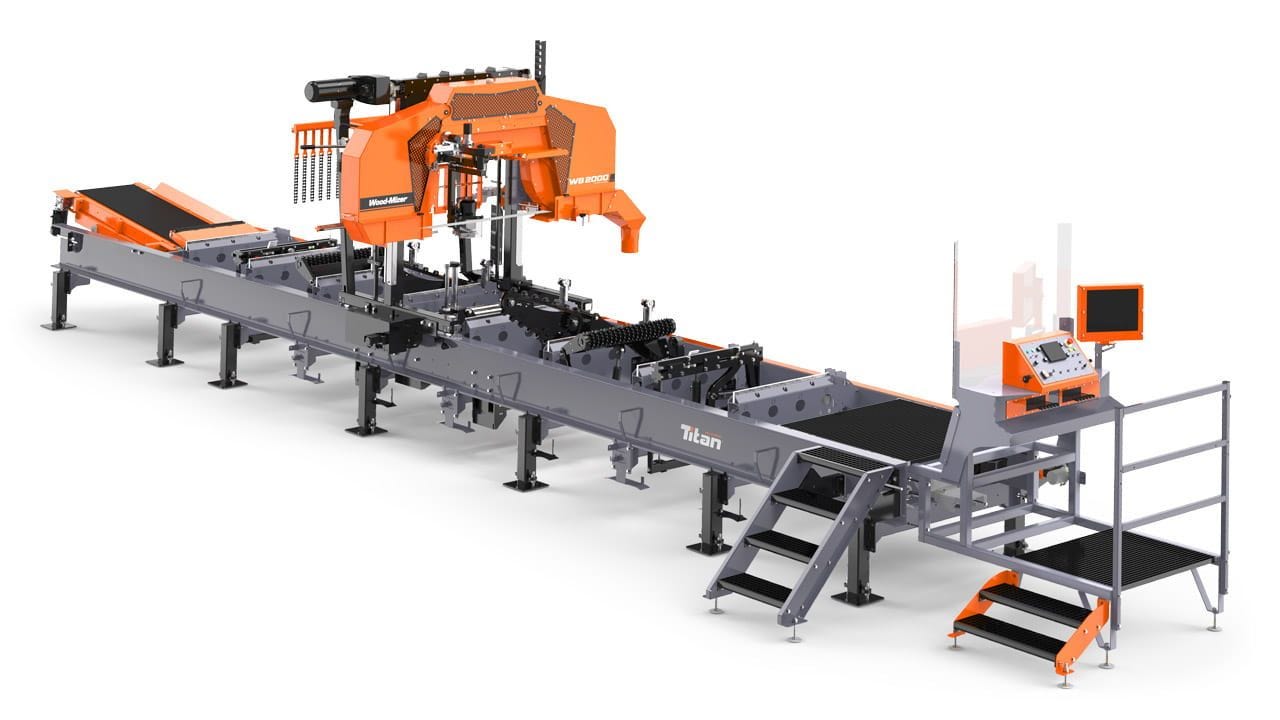

Titan wideband sawmill WB2000

High Performance Wideband Sawmilling

The Wideband WB2000 Sawmill features EXTRA heavy-duty construction, low maintenance requirements, and efficient operation.

Доступно за замовленням, від:

Доступно за замовленням, від:

Original price was: 150,080 €.145,340 €Current price is: 145,340 €.

Wood-Mizer’s knowledge of customer needs in international markets has delivered a sawmill that is the best that both narrow and wideband technologies have to offer.

Wood-Mizer’s WB2000 features heavy-duty construction, low maintenance requirements, and efficient operation. The WB2000 uses wideband 75 mm blades or 100 mm stellite-tipped blades. When using 75 mm blades (available with 22.22 mm and 28.50 mm tooth spacing) the sawmill is especially cost-efficient in terms of blade maintenance costs. To ensure the best visibility of the cutting and log handling processes we offer an optional live-feed video system with two cameras as standard, expandable up to four cameras.

The PRO version of the sawmill uses an automatic PLC setworks system.

The 12-inch touch-screen displays various parameters such as the dimensions of the material, current head height, feed position and main engine power. To adjust these parameters, the operator simply has to use the touch screen to enter new settings.

The EC version uses a 5.7-inch touch-screen with the latest version of the SW PLC3 Setworks system.

The modern, heavy-duty bed has a log capacity of up to 6 tonnes. The massive twin C-channel steel beams that make up the frame are 400 mm tall by 110 mm wide. All hydraulic log handling functions – such as the log clamps, chain turners, power rollers, side supports and hold-down clamps – are modular, and can be moved to different bunks as needed.

The WB2000 can be used used as a standalone sawmill to fully process a log, or in addition to an existing business to process irregular logs or to produce custom orders that the existing equipment is not suited for. Thanks to the various hydraulic packages and bed lengths, the sawmill is very versatile. It can saw large diameter softwood, hardwood and tropical logs from 2.4 meters up to 12 meters.

Features

Operator Station (PRO version)

The raised platform with an operator’s chair and two joystick controls is equipped with a modern touch-screen control panel, shown here with the optional camera display system

Operator Station (EC version)

The operator station is equipped with an integrated control panel with all head and hydraulic functions

Joystick Controls (PRO Version)

Control the sawmill with ergonomic joysticks

Touchscreen (PRO Version)

The 12-inch touch-screen displays various parameters such as the dimensions of the material, current head height, feed position and main engine power

Various Log Handling Packages

Modular hydraulic components adjust to your requirements

Bi-directional Chain Turner

Equipped with a chain turner for quick log turning

Log Leveling and Cant Removal Roller

Used for positioning the log in the optimal place on the bed, and also for removing cants from the sawmill

Belt-conveyor

Located at the rear of the bed. Activates automatically when the head returns, ensuring efficient material flow. Tilt angle can be adjusted

Cameras; Screen

Ensures complete oversight of the cutting process. The standard version is equipped with 2 cameras, and up to four cameras can be mounted

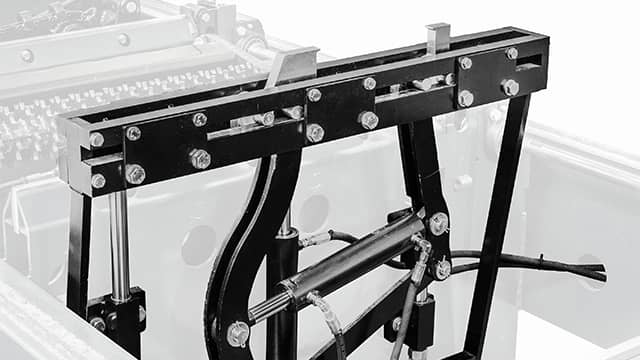

Central Clamp

Clamps and stabilises the log during the cutting process and is also used to turn squared cants

Debarker

Removes dirt and rocks from the blade path, keeping the blades in better condition between sharpening, and extending overall blade life. Available as an option

Hold Down Clamps

Clamps the cant from two sides during cutting. Excellent for cants with internal stress

Videos

Specifications

| POWER SELECTIONS | |

|---|---|

| Power Selections | 30 kW (40 HP) Electric 37kW (50HP) electric |

| CUTTING CAPACITIES | |

| Max. Width of Cut | 90 cm (35 1/2″) |

| Max. Log Length | 5.2 m (S Bed) 8.2 m (M Bed) |

| Min. Log Length | 1.2 m (4.6′) |

| Min. Log Diameter | 20 cm (8″) |

| Log Weight | 6t (13,228lbs) |

| BLADE | |

| Blade Length | 6,000 mm (236″) |

| Blade Guides Style | Double Block Guides |

| Blade Lubrication System | Automatic Blade Oil Lubrication |

| Blade Tension System | Hydraulic Tension System with a Pressure Accumulator |

| Blade Wheel Type | Crowned Steel Wheels Special Blade Wheels for 75 mm blades |

| Blade Width | 75 mm (3″) 100 mm (4″) |

| HEAD FEATURES & OPTIONS | |

| Laser | Optional Laser |

| Board Removal | Board Return System |

| Log Debarking | Optional |

| Blade Guide Arm | Adjusted with Control Switch |

| Blade Engagement | On/Off Button (Electric Versions) |

| Head Forward/Reverse | Variable Speed Power Feed |

| Setworks | PLC Industrial Setworks |

| Operator Location | Standing Platform with Operator Controls (EC) Platform with operator’s seat and joysticks system (PRO) Air-conditioned Cabin |

| Observation Cameras | 2 Cameras Included (CE Markets only) 4 Cameras |

| BED FEATURES & LOG HANDLING | |

| Side Supports | 2 or 4 Vertical Side Supports |

| Hydraulic Speed | Dual Speed Hydraulics activated with foot pedal |

| Board Removal Conveyor | Board Removal Conveyor (Optional) |

| Hydraulic Output | 18LPM (4.8GPM) 27LPM (7.1GPM) 55LPM (14.5GPM) |

| Cant hold-down clamps | 2 Cant Hold-Down Clamps (Optional) |

| Log Leveling | 2 Powered Leveling Rollers |

| Log Turning | 1 or 2 Bi-directional Chain Turners |

| Log Loading | Log Deck (LD2) |

| Log Clamping | 1 Hydraulic Log Clamp |

| Hydraulic Pump | 5.5kW (7HP) 7.5kW (10HP) 11kW (14HP) |

| MACHINE DIMENSIONS & REQUIREMENTS | |

| Delivery Methods | Container or truck |

| Bed Construction | Twin Rail |

Reviews

There are no reviews yet.