Multirip Board Edger EG300

Efficient, Multi-rip Edging

With both edger and multirip functions, maximise recovery from each board and increase sawmill productivity.

Доступно за замовленням, від:

Доступно за замовленням, від:

21,525 €

The EG300 combines the functions of both an edger and a multirip into one machine. The EG300 maximises recovery from each board and increases overall productivity of your sawmill by 20-30%.

As standard, the EG300 is supplied with two circular sawblades for use as an edger. One blade is fixed and the other is adjustable from the operator control console – using the electronic Setworks system to accurately pre-set the required width of the board. Optional lasers can be installed to assist the operator in determining the precise width for maximum recovery.

The EG300 comprises three main components – the main saw unit, the infeed table and the outfeed table. This modular construction ensures easier transportation, handling and installation.

Two top rollers make it easy to move a board back to the front of the edger for a return pass. An adjustable fence allows the operator to quickly position boards with an already straight edge.

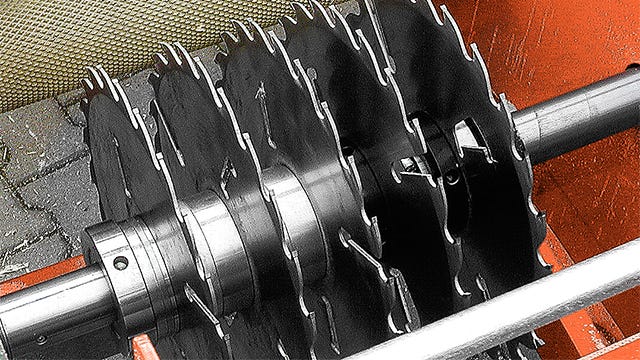

Optionally, the EG300 can be fitted with up to five circular sawblades for multirip applications. Four of the blades are fixed for cutting standard widths and the fifth is movable. Changing between edger and multirip operations is simple, and this flexible design allows the operator to react quickly to changing demand. Power feed is variable from 0-20 m/min.

Features

MultiRip Blade Kit

Add three additional blades for full function multi-rip capability

Standard Setworks

Uses rugged electronics to quickly position adjustable blade in accordance to required cutting width

Electric motor

15 kW (18.5 kW optional)

Top rollers

Make it easy to return boards that require a second pass

Adjustable Fence

Allows you to quickly position boards that already have one straight edge

Powered Rollers

Full width steel rollers grip wet boards firmly without damaging the surface

Videos

Specifications

| POWER SELECTIONS | |

|---|---|

| Power Selections | 8.5kW electric 15 kW (20 HP) Electric 18.6 kW (25HP) Electric |

| CUTTING CAPACITIES | |

| Min. Width of Cut | 20 mm (.75″) (multirip) 60 mm (2.36″) (edging) |

| Max. Material Thickness | 60mm (2.36″) |

| BLADE | |

| Blade Speed (RPM) | 2940 RPM (50Hz) 3520 RPM (60Hz) |

| Number of Blades | 2-5 |

| Blade Diameter | 350 mm (13.75″) |

| Blade Kerf | 4 mm (0.16″) |

| Blade Adjustment Method | Electric |

| Blade position | Fixed on right side |

| FEED SYSTEM & OPERATION | |

| Feed Speed | 0-20 m/min (0-65 ft/min) |

| Board Kickback Prevention | Anti Kick-back fingers |

| Board Alignment | Optional Lasers |

| Straight Edge Board Fence | Adjustable Board Fence |

| Material Hold-down | Powered Steel Rollers |

| MultiRip Function | Optional MultiRip |

| Operator Controls | Stationary Control Station |

| Setworks | Setworks |

| Feed System | 4 powered rollers |

| Options | Outfeed table Cant outfeed tailer |

| MACHINE DIMENSIONS & REQUIREMENTS | |

| Sawdust Collection Port Diameter | 150 mm |

| Electrical Requirements | 400V 50Hz 3Ph 40A |

| Safety Standards | CE |

Reviews

There are no reviews yet.