PLANER / MOULDER / RIPSAW MP220

The MP220 efficiently combines moulding, planing and ripsawing in one machine

Designed for a variety of woodworking projects, the MP220 is the best choice for sawyers and carpenters who value high-capacity, premium quality and versatility.

DESCRIPTION

The MP220 multi-purpose woodworking machine was designed to meet the demands of sawyers and carpenters working on a variety of projects. It’s a great choice of affordable equipment for woodworkers at every level – from an enthusiast small workshop to a professional woodworking company. It’s versatile, compact and economical.

This moulder/planer/ripsaw machine combines these 3 important operations in one single unit, increasing productivity and therefore saving time. In addition to all Wood-Mizer Woodworking Machines, the MP220 is an ideal solution for sawyers and carpenters who want to process more timber in a relatively short time. The MP220 features two sawdust extraction ports (125 and 100 mm) on top of the main cover, and one (50 mm) under the cast iron table, helpful in keeping the work area clean.

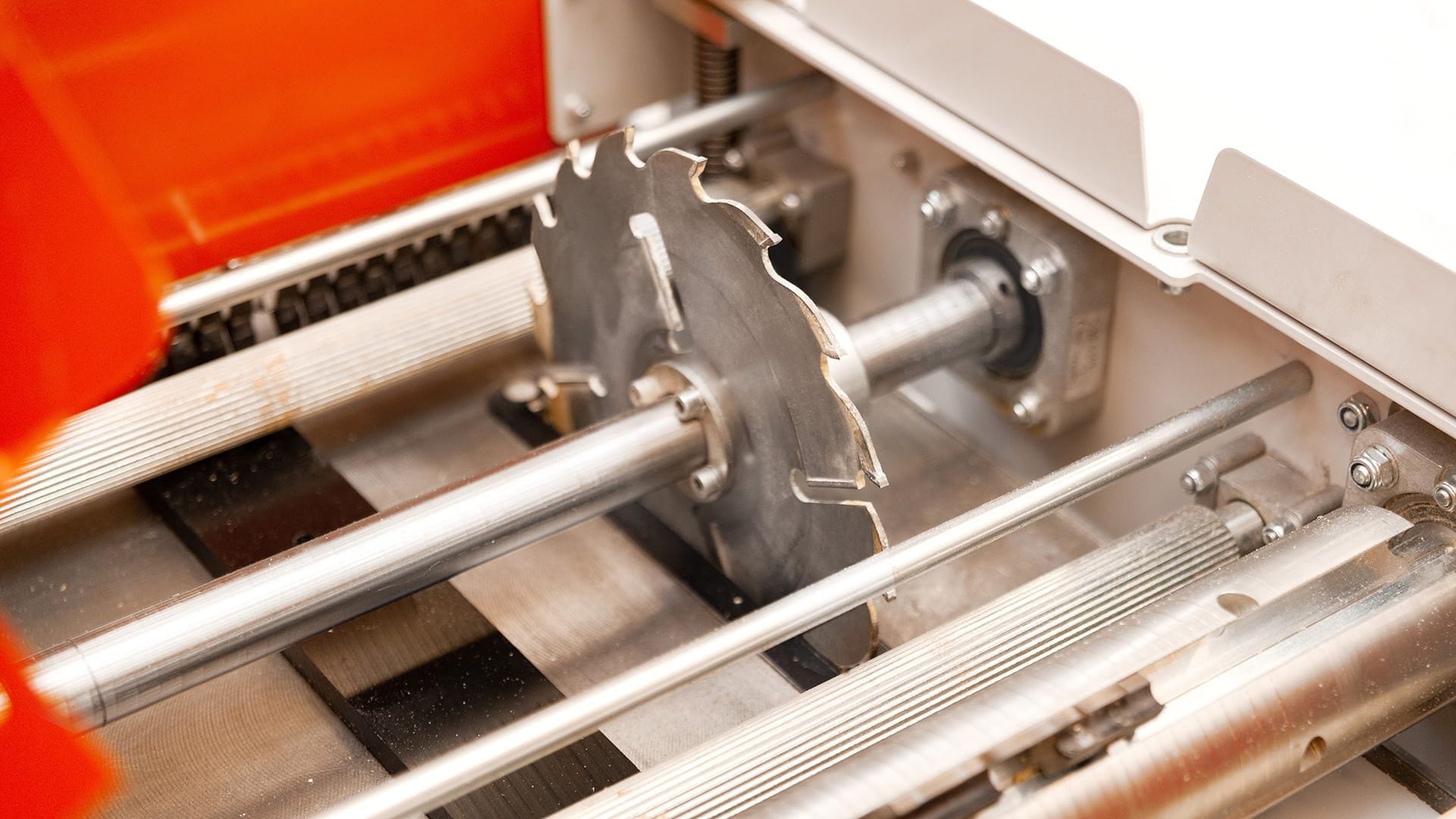

Ripsawing is optimized for safety and ease of use. The ripsaw blade is hidden under the top cover and can be easily adjusted by the operator. With a maximum ripsawing height of 80 mm, feeding of material on a cast-iron table is smooth and secure. Over the feed table, there is a control unit, allowing for easy operation of the machine. The machine works with a set feed speed of 5 m/min (ECO version), or at a variable speed of 2-11 m/min (PRO version).

The MP220 machine is highly versatile, so it can turn every woodworking idea into a final product. It’s an indispensable tool for both amateurs and professionals who would like to make their own quarter rounds, floor decking, panelling, crown mouldings or wide floorboards. Most of these products can be made in one pass, while other, more advanced mouldings require 2 or 3 passes through the machine. The electrical motors provide the rotation speed of 6000 rpm, ensuring a smooth surface on the final products.

It has been designed, like all Woodworking Machines, as a high-quality and sturdy tool, built around a cast iron table, to ensure the precision of ripsawing and the best results of moulding/planing. Cutting knives offer the maximum depth of moulding at 20 mm. Maximum planing dimensions are 400 mm wide and 240 mm high.

Working with the MP220 can begin just after unboxing the machine, but it can be adjusted as required with the help of accessories available from the Wood-Mizer TOOLS range. It’s very easy to change the configuration of the cutterhead by adding knives or adjusting the blade for ripsawing. Its compact size, lightweight construction (240 kg) and optional transportation wheels make moving it around the workshop quick and effortless.

The MP220 is shipped on a small pallet (120 x 105 x 136 cm).

FEATURES

Three operations in one machine

Combines moulding/planing/ripsawing in one unit, while saving time and increasing productivity.

Compact construction

Lightweight and compact, with transportation wheels (optional) makes setting the machine in the workplace quick and easy.

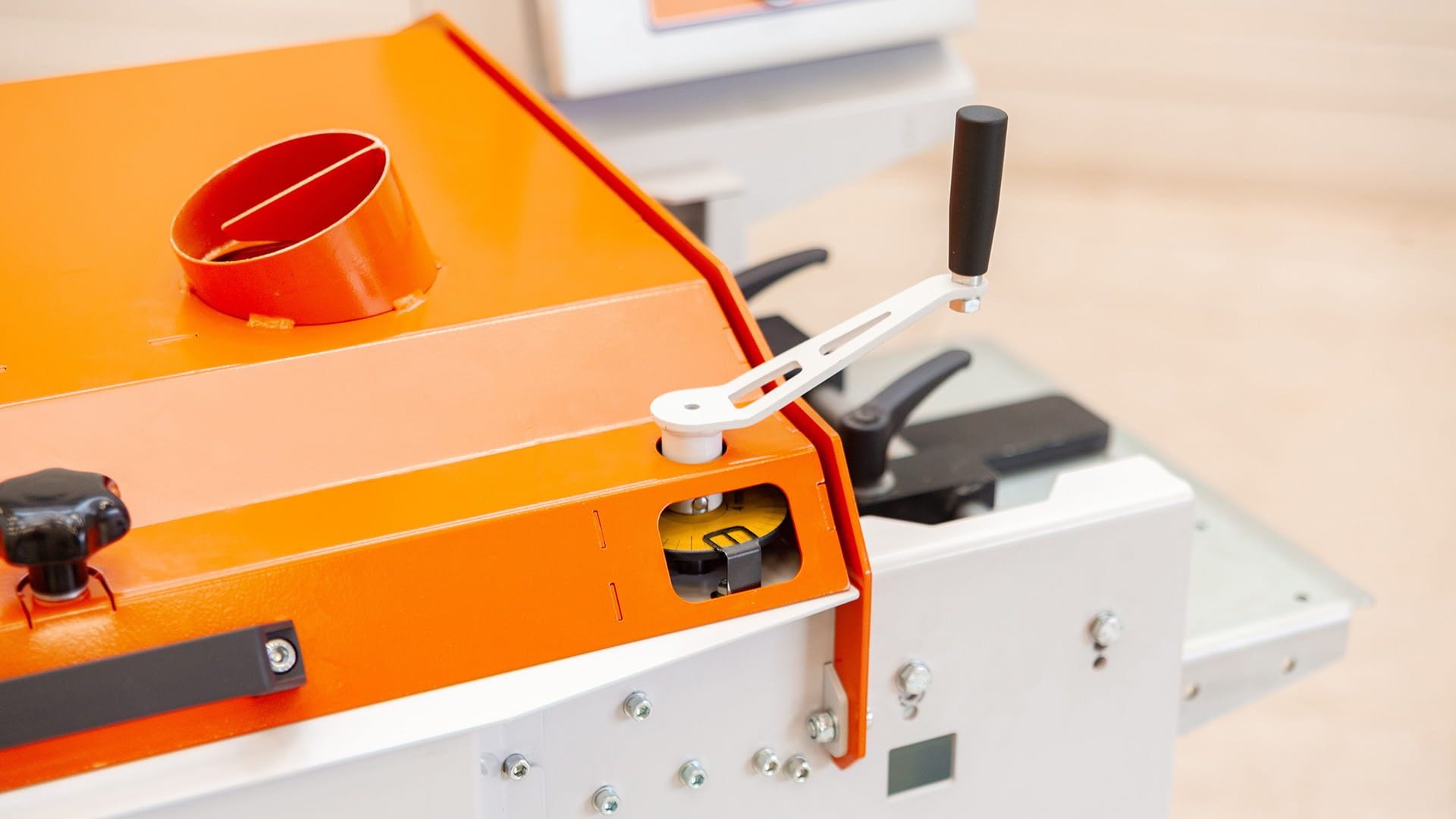

Top cover

Shields safely the resaw blade and the cutterhead, with extraction ports for sawdust removal.

Easy adjustment

Ergonomic hand crank for adjusting the height of cast iron table and a ledger for positioning the material while ripsawing.

Operator panel

Convenient operator unit with controls placed over the in-feed table.

Additional accessories

Wide selection of extras offered for the machine include (profile knives, ripsaw blades, extension tables, caster wheels, etc.).

VIDEOS

SPECIFICATIONS

| MATERIAL CAPACITY | |

|---|---|

| Max. Material Width | 400 mm |

| Max. Material Height | 240 mm |

| Min. Material Height | 15 mm |

| Min. Material Length | 470 mm |

| HORIZONTAL CUTTER | |

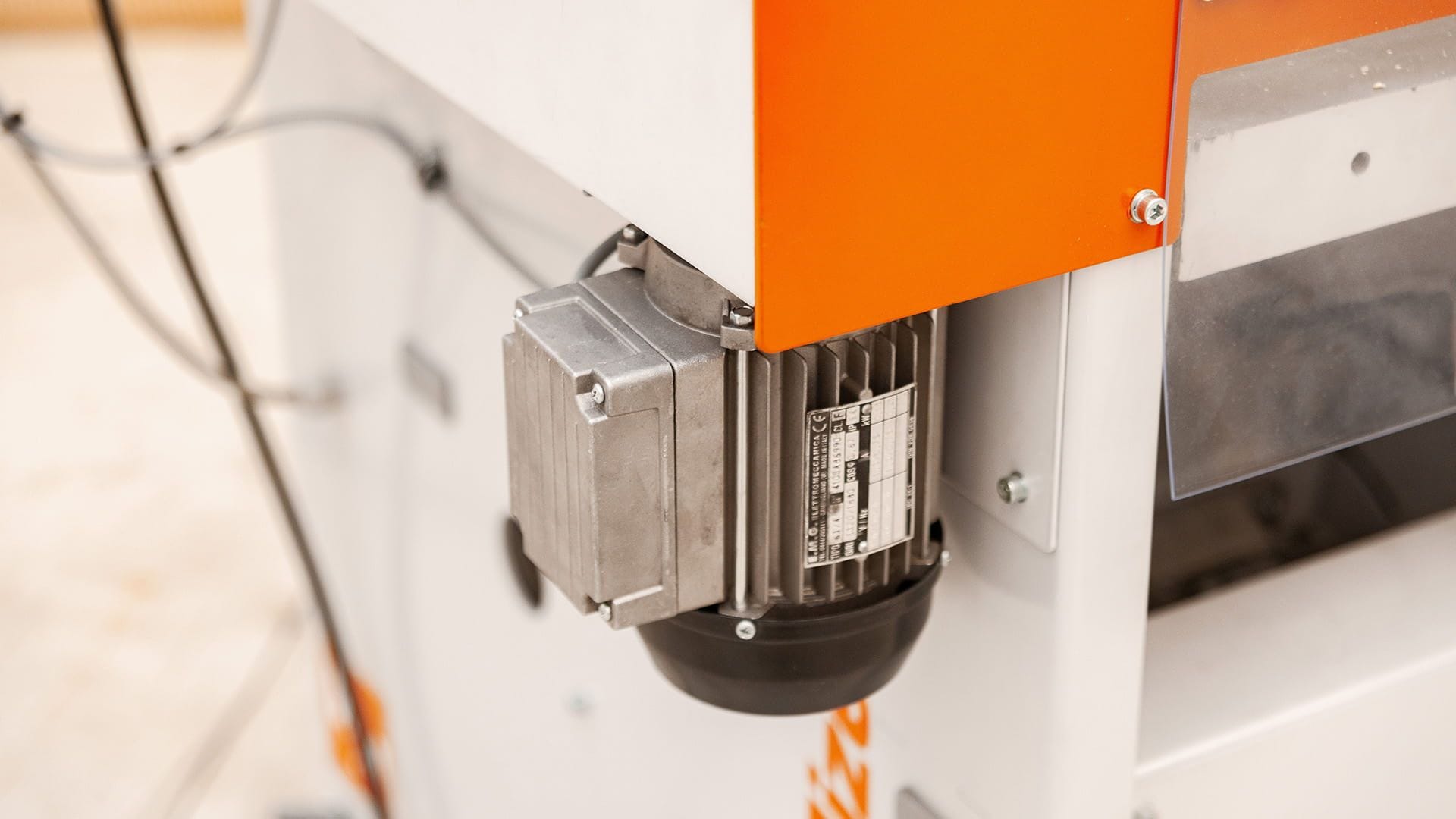

| Motor | 3 kW (Set Feed Speed) 4 kW (Variable Feed Speed) |

| Diameter | 72 mm |

| PLANING | |

| Max. Planing Width | 400 mm |

| Max. Cutting Depth | 4 mm |

| MOULDING | |

| Max. Cutting Depth | 20 mm |

| RIPSAWING | |

| Max. Ripsawing Width | 280 mm |

| Max. Ripsawing Height | 80 mm |

| CIRCULAR BLADE | |

| Diameter | 225 mm |

| Bore Diameter | 35 mm |

| FEED SYSTEM | |

| Feed Speed | 5 m/min 2-11 m/min |

| Feed Motor | 0.18 kW (0.25 HP) 0.37 kW (0.5 HP) (with planetary gearbox) |

| DIMENSIONS & WEIGHT | |

| Length | 1116 mm |

| Width | 788 mm |

| Height | 1257 mm |

| Cast-Iron Table Size | 650 mm x 410 mm |

| Weight | 240 kg |

| Shipping Weight | 360 kg |

| MACHINE STANDARDS & REQUIREMENTS | |

| Dust Extraction Ports | 50 mm 125 mm 100 mm |

| Min. Extractor Air Flow Rate | 2000 m3/h |

| Electrical Requirements | 3-phase, 400 V, 16 A 3-phase, 230 V, 16 A 1-phase, 230 V, 20 A (only set variable speed) |