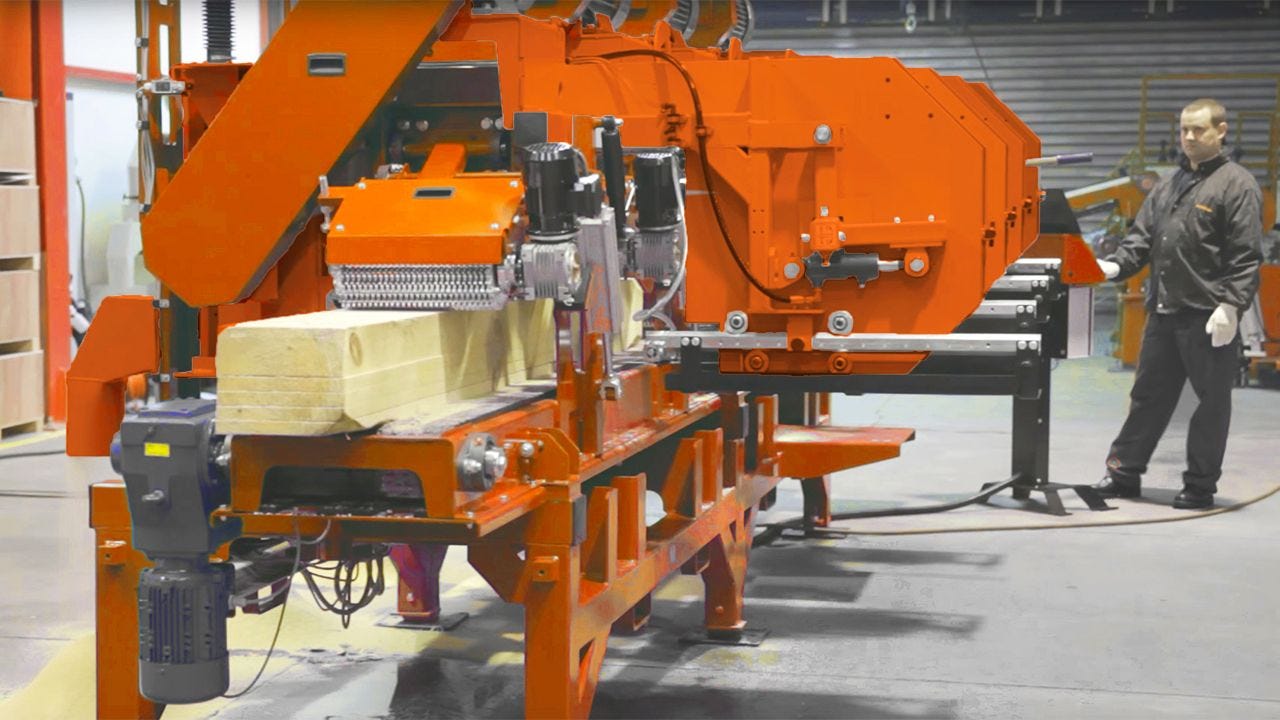

HORIZONTAL RESAW HR700

Modular, Multi-Head Horizontal Resaw

Expand from one to up to six cutting heads with the heavy-duty HR700 large capacity resaw.

DESCRIPTION

Ideal for companies that need a large capacity, heavy-duty multi-head resaw, the HR700’s modular design makes it easy to expand from one to a maximum of six heads as their demands change.

In its maximum six head configuration, the HR700 converts large cants into six boards and one slab in one pass. A separate control stand holds all controls for the resaw. Standard, head height is positioned with a manual screw. Optional Setworks with electric up/down are available, which increase speed and precision when adjusting the heads to produce different sized timber. Centralised blade tensioning for each two-head base makes the blade change process more efficient.

The twin-track steel belt conveyor provides a solid and durable surface that fully supports the entire cant width. Heavy, powered rollers stabilise and feed the cants through the heads during sawing. This makes it easier to process short cants or material with internal tension. A pneumatic sensor automatically raises the rollers to accommodate incoming cants. The roller speed is synchronised with the conveyor belt speed, providing more precise cutting, especially for thin boards.

The base HR700 module includes two heads as standard. To extend the resaw, all that is needed is to add another two-head module and install a longer conveyor belt. The modular design makes transportation easier and less costly, as well as giving businesses the option to scale up their resaw capability as their demands change.

FEATURES

Large Cant Capacity

Larger motors and 400 x 400 mm cant capacity.

Twin-track Steel Conveyor Belt

Supports the full cant width.

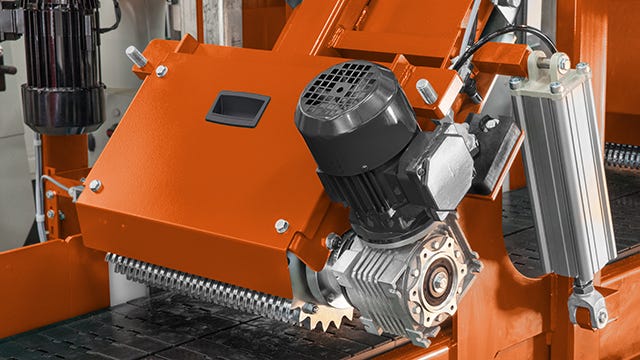

Central Blade Tension and Lubrication

Each module has centralised blade tension and lubrication.

Heavy, Powered Spiked Rollers

Designed to secure cants with internal tension firmly.

Optional Setworks

Increase operator productivity with the optional computer Setworks and electric up/down.

VIDEOS

SPECIFICATIONS

| POWER SELECTIONS | |

|---|---|

| Power Selections | 11kW (15HP) electric / per head 15kW (20HP) electric / per head 18.6kW (25HP) electric / per head |

| CUTTING CAPACITIES | |

| Min Cant Height | 6 mm (1/4″) |

| Max Cant Height | 400 mm (15.75″) |

| Max Cant Length | Unlimited (for more than 3.6m material length, additional tables required) |

| BLADE | |

| Blade Length | 4670 mm |

| Blade Guides Style | Roller Guides |

| Blade Tension System | Centralised Hydraulic Blade Tensioner for each 2 heads |

| Blade Wheel Diameter | 600 mm |

| Blade Width | 32-38 mm |

| HEAD FEATURES & OPTIONS | |

| Setworks | Optional Setworks |

| Head Up/Down | Electric Up/Down |

| Number of available cutting heads | 1-6 |

| Head Configuration | Horizontal |

| FEED SYSTEM & OPERATION | |

| Feed Speed | 0-20 m/min (0-65 ft/min) |

| Material Hold-down | Spiked Top-roller Hold-downs |

| MACHINE DIMENSIONS & REQUIREMENTS | |

| Normal Power Usage | 1 head 40 Amp (15 kW motor) 2 heads 75 Amp (15 kW motor) 3 heads 105 Amp (15 kW motor) 4 heads 140 Amp (15 kW motor) 5 heads 170 Amp (15 kW motor) 6 heads 200 Amp (15 kW motor) |

| Electrical Requirements | 400V 50Hz 3Ph |