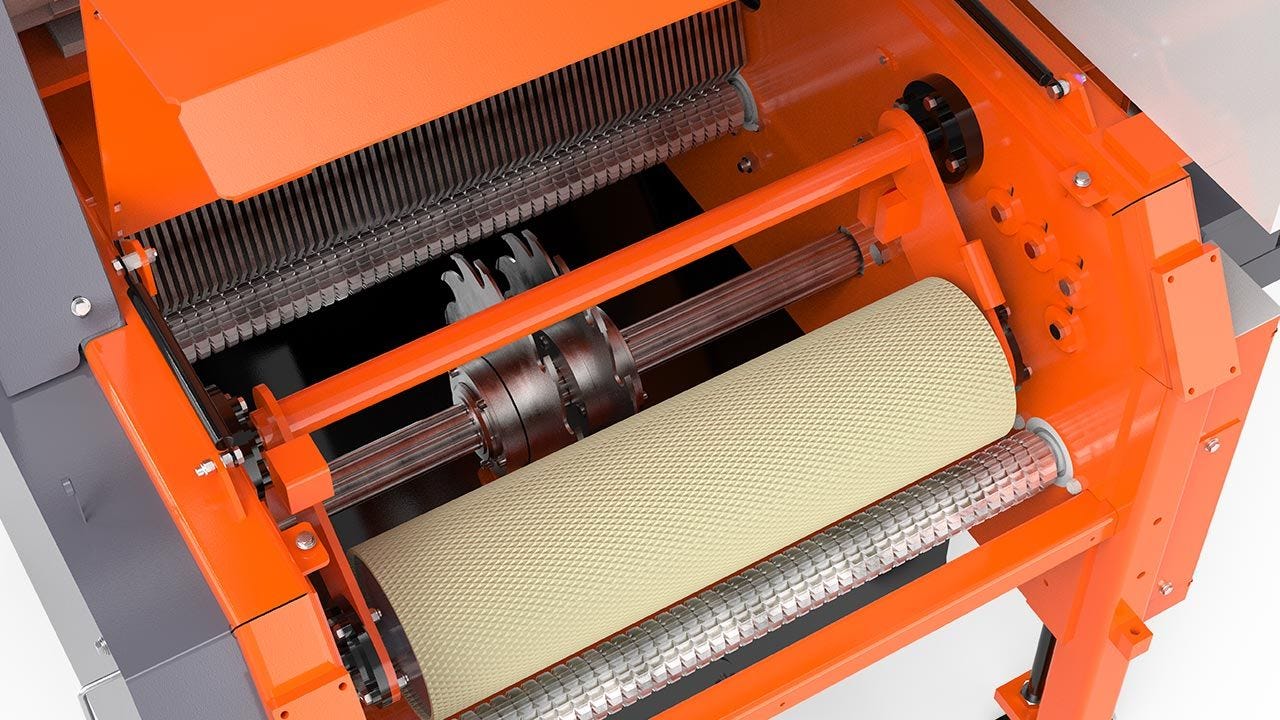

INDUSTRIAL TWIN BLADE BOARD EDGER EG400

Extreme, Heavy-duty Edging

Rugged board edger for commercial businesses that require a fast, accurate, and heavy-duty board edger.

DESCRIPTION

The EG400 is a rugged board edger that is at home in commercial sawing businesses that require a fast, accurate, and heavy-duty board edger. The EG400 edges material 700mm wide by 100mm high at 30 metres per minute, and smaller material at up to 54 metres per minute.

The remote operator’s control console manages all edger functions, and can be repositioned as needed. The 22kW motor delivers plenty of power for softwoods and hardwoods. The edger automatically adjusts feed speed depending on the thickness of the board being cut. Two 400mm blades are mounted on a splined shaft and move in and out from the centre, allowing the use of an optional outfeed board conveyor.

Two lasers are standard on the EG400 for board positioning, and it is equipped with anti-kickback protection and other safety features including a perimeter e-stop cable and electrically interlocked safety covers. The standard infeed table is available with optional rip fences.

An optional tailer outfeed keeps the edged boards moving through the line, while enabling easy waste removal. Optional electronic setworks are available.

FEATURES

Optional Setworks

This option includes both the LED 2″ display and remote control.

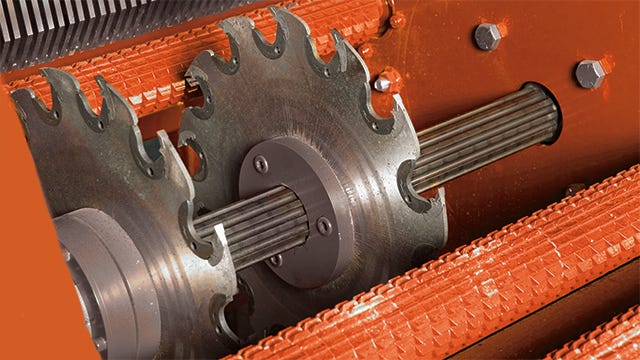

Two Moveable Blades

Easily access both 16” blades which move in and out from center on a splined shaft.

Two Lasers

Two included standard lasers help to determine correct board position, increasing yield and grade.

VIDEOS

SPECIFICATIONS

| POWER SELECTIONS | |

|---|---|

| Power Selections | 22 kW (30 HP) Electric |

| CUTTING CAPACITIES | |

| Max. Width of Cut | 72 cm (28″) |

| Min. Width of Cut | 76 mm (3″) |

| Max. Material Thickness | 100 mm (4″) |

| BLADE | |

| Blade Speed (RPM) | 2320 RPM |

| Number of Blades | 2 |

| Blade Diameter | 400 mm (16″) |

| Blade Kerf | 7 mm (9/32″) |

| Blade Adjustment Method | Electric |

| Blade position | Two Centered Blades |

| FEED SYSTEM & OPERATION | |

| Feed Speed | 100mm (4″) material: 13m/min (44 Ft/Min) 50mm (2″) material: 24m/min (78 Ft/Min) 25mm (1″) material: 34m/min (111 Ft/Min) |

| Board Reverse System | Reverses feed rollers to eject jams |

| Board Kickback Prevention | Anti Kick-back fingers |

| Board Alignment | 2 Lasers |

| Material Hold-down | Powered Steel Rollers |

| Operator Controls | Stationary Control Station |

| Setworks | Optional Setworks |

| Feed System | Rubber Infeed & Outfeed Belts |

| Options | Heavy-duty outfeed tailer |

| MACHINE DIMENSIONS & REQUIREMENTS | |

| Width | 1.6 m (64″) |

| Electrical Requirements | 400V 50Hz 3Ph 70A |

| Safety Standards | CE |